Is Your Apple Orchard Robot Ready?

This photo illustrates a 2-D fruiting wall planting and training system. (Photo: Apple and Pear Australia Ltd.)

Many reports on adopting robotic harvesters for apple harvesting have been encouraging in recent years. Replacing human pickers with robotic fruit harvesters would be a dream come true for apple growers. However, how long will it take to make the dream a reality? Depending upon who you ask, the answers can vary from as few as one to two years to as many as 10 to 20 years from now.

Leading Prototypes

The prototypes of robotic apple harvesters developed by Fresh Fruit Robotics (FFRobotics) and those by Abundant Robotics appear to be the most advanced ones in the robotic field. Currently, they are being tested in commercial orchards in Washington State and elsewhere. The system by FFRobotics has multiple robotic arms; each arm has three-fingered grips to grab fruit. The machine could pick up to 10,000 apples an hour. The robotic picker by Abundant Robotics uses a vacuum to suck apples off trees at one fruit per second.

The advanced sensing and detection technologies are integrated into these robotic systems, making them remarkably accurate in fruit detection. However, the robots only can pick the fruit directly accessible to them. They are not able to go around obstacles that block the fruit from being reached, such as trellis wires and old branches. In addition, the robotic systems may cause high damage or dropping rates when picking fruit clusters.

If tree canopies are trained so that almost each fruit is accessible and well spaced, the robotic systems are capable of picking most fruit off the trees. This process of training tree canopies is called ‘robot ready.’ If orchards are not robot ready, the robotic systems will not work well. The 2-D fruiting wall planting system is considered a good fit for these robotic harvesters.

Challenges to Adoption

Most orchards in the U.S. are not considered robot-ready. Evolving existing tree canopies to robot-ready canopies requires time and investment. This is a major challenge in order to use robotic apple harvesters. It is probably more feasible to apply the training system to new orchards with robotic harvesting in mind.

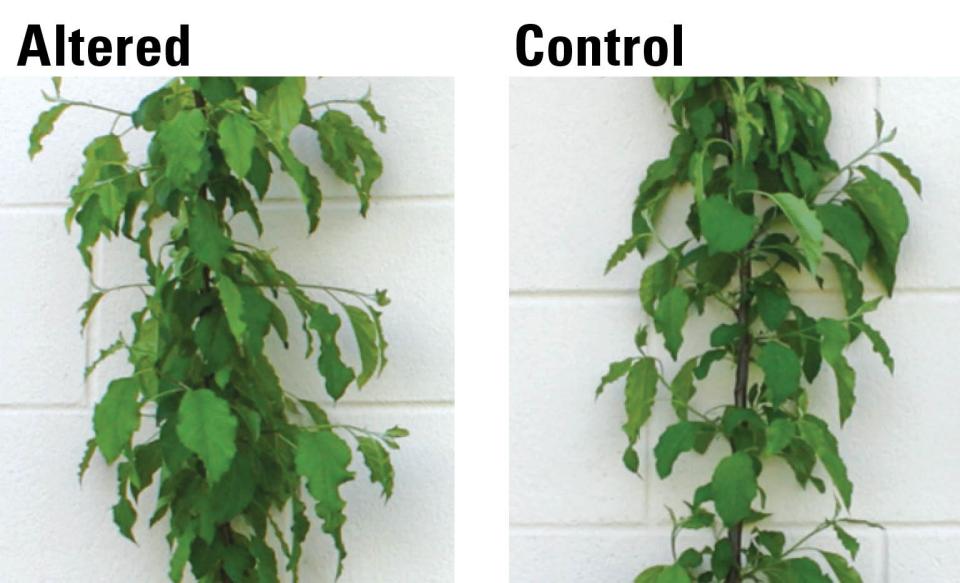

Altering a weeping gene expression in a standard apple leads to branches spreading more than the control. (Photo: Kenong Xu)

However, the recommended orchard replacement rate is 5% per year. It will take 20 years to replace an existing orchard with new plantings.

Another challenge is the cost and reliability of these robotic systems. If the cost efficiency ratio of the robotic harvesters is not competitive, it will be impossible to replace human pickers.

Improving Tree Architecture

The modern history of apple production is largely about keeping trees in optimal shape to increase orchard productivity and profitability. To date, optimizing tree canopies has been through innovations in tree training systems and genetic improvement of apple rootstocks.

Several tree-training systems are used in today’s orchards in the U.S., including the organized trellis systems (V-trellis and vertical trellis), tall spindle, and 2-D fruiting wall. The development of these tree pruning and training systems has played an indispensable role in shaping the trees, including in making tree canopies robot ready.

The development of dwarfing rootstocks in tree size and height control represents the most important accomplishment in genetic improvement of apple tree architecture. Dwarf rootstocks have fundamentally transformed the apple industry. Without using dwarf rootstocks, many innovations in orchard planting and training systems would not be possible.

Efforts to genetically improve the scion architecture have focused on developing columnar apple cultivars, originally discovered as sport mutation from ‘McIntosh’, called ‘Wijcik McIntosh’ in the 1960s. Columnar apple trees are characterized with simple and narrow canopy due to a reduced number of branches and vertically growing branches. Columnar trees bear fruit on spurs emerged on “old wood” such as the main trunk and require little pruning. Multiple studies reported that the columnar trait is controlled by a single gene called CO.

Although many columnar cultivars were named and released, none of them were accepted and grown widely by the apple industry due to a lack of vigor for rapid orchard establishment and their strong tendency to excessive and alternate bearing.

However, the beneficial characteristics of a columnar growth habit represent a unique opportunity in genetic improvement of scion canopies, which are considered more suitable for robotic harvesting. Encouragingly, a recent study showed that regular annual bearing was observed on some columnar apple selections. Regarding low tree vigor, our own study confirmed that combining high vigor with columnar is easily achievable.

More importantly, we recently identified at least one more gene involved in columnar phenotype in addition to the columnar gene CO, which broadened our understanding of the columnar trait considerably. It might be possible to use this gene to modify the columnar trait to mitigate the associated biennial bearing and low-vigor traits.

Weeping growth habit stands are another opportunity for genetically improving tree canopies, as branch tying down is practiced in some leading orchard systems, such as tall spindle, 2-D fruiting wall, and solaxe. We recently have identified a major weeping gene in apple. Interestingly, altering the expression of this gene in a standard apple cultivar led to branches spreading or growing downward.

These advances implicate that research findings in genetics of apple tree architecture may offer another effective means to improve scion canopies directly for robotic harvesting.