Real-Time Water Data Delivers Big Opportunity for Fruit and Nut Growers

FloraPulse’s microsensor can give growers up-to-the-minute water status data in their trees and vines. (Photo: Michael Santiago)

Reading plant stress can be a difficult endeavor, especially for nuts or wine grapes, where deficit irrigation is desirable near harvest. Currently, pressure chambers are the most common way to measure plant stress.

“It’s a big heavy instrument. You cut a leaf off and you stick it in the chamber, and you have to increase the pressure,” Alan Lakso, Emeritus Fruit Crop Physiologist with Cornell University, says. “It’s a slow, manual process, and then you get a reading of what the stress is that one moment that you took the leaf off.”

It’s accurate, but Lakso likens the pressure chamber’s reading to the stock market at 2 p.m. on a Friday. You’re getting information on a very dynamic system, and only at a fleeting moment in time. He wanted something that could give growers up-to-the minute readings of a plant’s water status.

This is where a promising new technology in the form of a microsensor comes in.

Lakso worked with a team of engineers at Cornell to ditch the pressure chamber and give growers a more accurate way to assess their trees’ or vines’ water status continuously.

But the development of this process didn’t happen overnight.

Inspiration for the Design

Because growers don’t have the whole picture of the plant’s water status, they often are irrigating too much or too little. And irrigation use varies regionally and with the weather. In the East, irrigation isn’t all that common. But in the West, the timing of irrigation — or lack thereof — is especially critical for the different stages of wine grape and nut development.

Lakso says that aside from the pressure chamber, soil moisture monitors can be a bit inefficient with their readings. Tree and vine roots aren’t dense, but they do go deep and spread out.

“You’re never sure whether your probe is near the roots,” he says. “You don’t know whether they’re getting the water from the top foot, or the middle foot, or maybe 20 feet down.”

“[The plants are] large and they’ve got to pull water through those little tiny vessels in the wood,” he says. “It’s like trying to drink through a tiny little straw.”

Lakso says this makes the trees or vines respond strongly to the weather and demand for water.

Long Time Coming

Lasko has wanted to directly monitor a plant’s water status for nearly 25 years. He says something as critical as water levels needs to be monitored more often since levels can be so variable.

“I thought, ‘Boy, it’d be nice if we could make some type of little tiny sensor we could put inside the plant that would just tell us what the stress is,’” he says.

It would have to wait until he learned of nanotechnology. In 2007, colleague Abe Stroock, a Professor in Cornell University’s School of Chemical and Biomolecular Engineering, was studying the physics of water stress in plants.

“I said, ‘I think you’ve got the physics and the technology, and we’ve got the problem,’” Lakso says.

So Stroock and Lakso started to develop the microsensor. Stroock’s then-Ph.D. student, Michael Santiago, took over the project from a previous grad student, Vinay Pagay, who did the initial work. Santiago took the device from prototype to reproducing the sensor for commercial test. Six months later, Santiago had built the first functional sensor prototypes.

From there Stroock, Lakso, and Santiago did follow-up testing and then formed a company called FloraPulse. Santiago serves as the company’s CEO. FloraPulse has received Small Business Innovation Research awards from USDA and National Science Foundation for $925,000. The project also received the USDA Prize for Innovations in Food and Agriculture in 2016.

“Our goal is for the sensor to consistently measure the same values as the pressure chamber for five or more years,” Santiago says.

Developing the microsensor was not without its own challenges. The sensor had to be designed to be rugged because it will be living in an orchard environment within a living, growing plant.

“We’re taking the electronic sensor, and we’re sticking it in a wet environment inside a tree, in an erratic natural environment,” Lakso says. “For electronics, it’s a pretty harsh environment.”

How It Works

How It Works

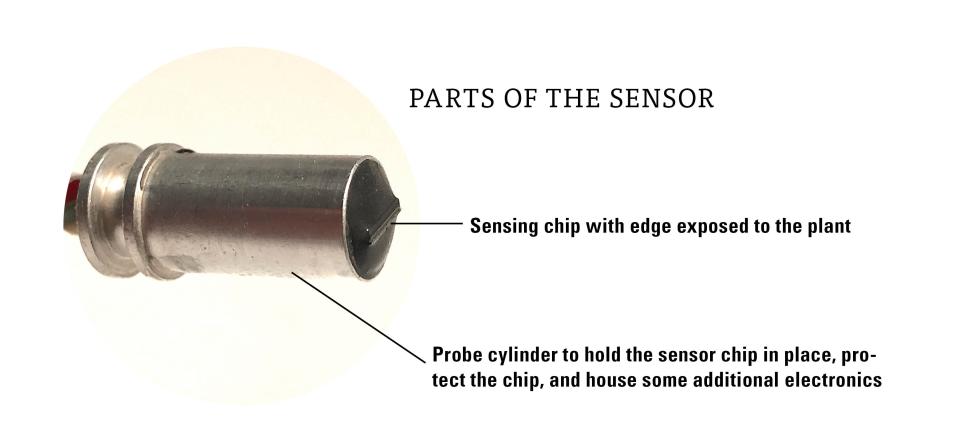

The microsensor is a very small chip held in a cylinder about a quarter-inch in diameter, Lakso says. The device has cellular wireless transmission that sends the readings back to FloraPulse’s website or to an app on a grower’s phone.

“The data is stored on FloraPulse’s cloud,” Santiago says. “It’s all encrypted. We have an app where [growers] can see the information, along with potential recommendations.”

To install the sensor, a grower drills a hole then inserts a cylinder sleeve with the sensor in it. The sensor rests against the water vessels in the tree or vine, and that’s where the tree and sensor exchange water. Then the sensor is sealed in.

It takes five minutes to install the sensor, which then takes continual readings of the plant’s water stress, Santiago says.

“When the plant loses water in the middle of the day and it gets drier, it will try to take a little water out of the sensor,” Lakso says. “And then at night, the tree reabsorbs soil water, so there’s more water in the plant and less in the sensor. The water will gradually move back into the sensor, and the pressure will go up. We can measure that.”

Lakso says the research team and growers are concerned about each plant type’s reaction to the installation process. But Lakso says the reaction has been limited.

“The advantage is that we’ve got a really small sensor and, with precision drill bits, we can drill a really nice clean hole,” he says. “If we drill those in a nice, clean way and then plug it immediately with the sensor and then seal it, we don’t get much wound reaction.”

Lakso says there’s a lot of data logged, but perhaps the most critical is the daily maximum and minimum water stress for the plants.

“It’s not any exotic new concept,” he says. “It’s a well-known physical principle used for years in soil tensiometers.”

The thought is the sensor would last for at least one season, depending on the growth of the tree and vine.“We expect that after three to five years, the plant will outgrow the sensor,” Santiago says.

The stainless housing or sleeve holds the probe in the wood and the wires take the signal to a data recorder or wireless transmitter. (Photo: Alan Lakso)

In the Field

The first microsensor field testing took place in 2016 on apple trees and grapevines at Cornell’s research farms.

“We showed that it actually can work. It gives us minute-by-minute data of the stress in the plant. When the clouds go over, there’s less stress, and you can see the change,” Lakso says. “So, the thing actually worked.”

The researchers also tested the sensors in vineyards and almond orchards at the University of California, Davis, vineyards in the Napa Valley, CA, and almond orchards in Arbuckle, CA. There’s also been testing in corn and apples in New York.

“EJ Gallo has been extremely helpful in different ways, including research support,” Santiago says. “Last year’s field trials showed the sensors can work reliably for years.”

Future Plans

For now, FloraPulse will be limiting its release next year to almond and grape growers in California. This microsensor could help with deficit irrigation to induce consistent hull split in almonds or to improve winegrape flavors with controlled stresses at specific developmental stages.

So for growers “this gives them a tool where they can really dial in that level of stress,” Lakso says.

For installation, the size of the tree and vine will also be important. Plants should be no smaller than perhaps an inch-and-a-half or 2 inches in caliper. The team is perfecting installation so growers will get a consistent tight fit.

“We’re working on different designs of a sleeve. You install the sleeve and then the sensor slides into that,” Lakso says.

Stroock is also developing a model showing how the water moves to and from the tree, how weather and soil moisture can affect the system, and how trees express that water stress.

“We are working to distill the sensor information into clear-cut recommendations,” Santiago says. “There [are] many details that go into using the information correctly. The measurement by itself doesn’t tell you the whole story. You want to look at the number and the history of where the plant has been for the last few days.”

FloraPulse plans to expand the list of crops the sensor can be used in the future. And there’s also the thought that some of Lakso’s own models may find a fit within the sensor’s readings.

“We’ve never had this kind of continuous stress data before. We always had to use a more general approach,” Lakso says.

Santiago says pricing is still to be determined, but almond and grape growers who are interested can contact Santiago at FloraPulse.com.

“We’re targeting this to be a foundational tool for irrigation,” he says. “We’re trying to hit the right price point so that its use is widespread. We’re figuring that out as we go.”

Santiago sees this sensor as a key part of closed-loop irrigation or automated irrigation.

“Automated irrigation systems need to know the plant water status to determine when to put water on it,” he says. “Technology like this is foundational to that. They need to have good feedback to be able to determine when to turn on the valves.”

With water use regulations, especially in California, growers will have data to back up their compliance. And, growers could see higher yields and returns by knowing exactly what type of water needs their plants have, while keeping them at a consistent, optimum irrigation level.

“The point of this technology is to help the grower really be able to manage the plant more accurately by literally knowing the thirst of the plant,” Santiago says.