Old Trick Shines New Light On Citrus Food Safety

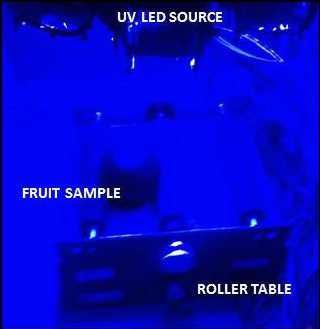

Inside the UV-C prototype packing line, an array of high-output UV-C LEDs treats a piece of citrus fruit positioned beneath.

Photo by Kevin M. Folta

Over the last decade, we’ve seen the use of light emitting diodes (LEDs) explode throughout the world of lighting. Everything from Las Vegas marquees to our home light bulbs now are driven by inexpensive, durable, and energy efficient LED light. LED lighting is now finding its way into horticultural applications, and we are seeing its use in greenhouses and growth chambers designed to produce better plant products.

Last year, there was interest from the Indian River Citrus League to design a system that could potentially use light to enhance the safety of citrus fruit. While treatment with visible light would not likely have much useful effect, it would be possible to use ultraviolet (UV) light to do the job of removing any lingering microbes that may have eluded the already stringent packing line safety measures.

UV light has been used to sterilize surfaces for a long time, and its germicidal properties are well known. Some UV qualities, such as the wavelength 260 nanometers (nm) light, or “UV-C,” damage DNA, and can be used to sterilize any surface, tool, or potentially piece of fruit. UV germicidal fluorescent lamps are routinely used in labs and hospitals, but are unfortunately not suitable for the packing line. They are made of fragile glass, they contain mercury, their intensity decays rapidly, and they require frequent replacement. Risks, limitations, and costs would likely outweigh any benefits. But, today there is a similar solution on the horizon that could get around these limitations.

Bright Idea

A number of manufacturers are initiating the production of UV LEDs. The UV LEDs now available emit at 260 nm wavelengths, the precise wavelength needed to destroy the DNA of microbes on any surface. The problem is that the devices are incredibly expensive, limiting simple tests with large scale arrays. However, the costs are coming down rapidly, so a limited trial with a small number of LED emitters could at least test if the approach could work, not damage the fruit and not damage the equipment.

Funding was obtained from the UF/IFAS Citrus Initiative Fund to build a prototype device and lab-size packing line. The software and electronics were engineered and built by Light Emitting Computers, a company specializing in horticultural applications of LED technology. They donated their efforts to this important project. I kept my neighbors awake on a late Tuesday night with a circular saw, cutting panels and supports for a cleverly designed UV-proof enclosure.

For the first tests, it was necessary to “dial in” the general parameters sufficient to kill microbes in a reasonable amount of time. The approach needs to treat fruit as it is whisked along the packing line without slowing operations.

These tests confirmed that UV LEDs can provide enough power to kill microbes in a petri dish, and even microbes (in this case laboratory E. coli) deliberately placed on the surface of an orange. However, 100% decontamination required more than a minute of treatment.

The results are cautiously encouraging, but of course, without much surprise. As mentioned in the beginning, UV light has been used to sterilize surfaces for a long time.

The other big question regards damage to fruit. Does the treatment cause scalding or even change postharvest quality? So far, there are no indications of negative effects, but it is something that needs to be carefully considered.

The Price For Progress

Now the real question is not if the technology will work, but rather if the cost of the LEDs will meet the value to the packinghouse. In other words, is there sufficient value in the effect to merit the cost of the lighting and installation? That answer will come in the near future, as the costs of actual implementation are coming down.

In the meantime, we are pressing forward with more rigorous laboratory experiments and recruiting assistance from food safety experts at the University of Florida. The technology will be tested against actual animal and plant pathogens, and the effect on postharvest quality will be carefully determined. Scientists need to identify the optimal treatment will sterilize the outside of the fruit, yet not damage the fruit itself, and that is a sweet spot that seems quite feasible.

The prototype will then be installed on the packing lines at UF/IFAS Citrus Research and Education Center or the USDA, and further evaluations will be performed. Solid performance will lead to introduction into the industry setting.

The use of UV LED lighting could provide a valuable tool to enhance food safety on citrus, and eventually on many kinds of fresh produce.