Researchers Develop Lower-Cost Options For Blueberry Harvest Assist Systems

The highbush blueberry industry continues to grow in this country, expanding to more than 61,000 acres in production. With this growth in production comes an increasing need for labor to maintain the bushes and harvest the fruit. As labor becomes more of a challenge for growers, a team of researchers is seeking mechanized solutions for this labor shortage.

Fueled by a $2.4 million USDA-National Institute of Food and Agriculture grant, researchers from the University of California, Berkeley; University of Florida; University of Georgia; Michigan State University; Mississippi State University; North Carolina State University; Oregon State University; Penn State University; Washington State University; and USDA’s Agricultural Research Service (ARS) seek to provide lower cost options.

Researchers have already developed a sensor to measure the impact of harvesting on the tender fruit, and this project seeks to pair the sensor with research into cost-effective mechanized harvest options for small- and mid-size growers.

Improving Ground Losses

Improving Ground Losses

“A highly efficient, affordable, intermediate harvesting system that could improve fruit quality and reduce ground loss would be welcomed by stakeholders of all farm sizes,” says Fumiomi Takeda, lead scientist at the USDA-ARS Appalachian Fruit Research Station in Kearneysville, WV, who is a co-principal investigator on the project.

Takeda says the research team is focusing on semi-mechanical harvest systems aimed at mid- and small-sized growers as an alternative to the commercial over-the-row harvesters now available on the market, while still improving labor efficiencies. The team is looking at shake and catch systems that could harvest ripe fruit gently and minimize bruising so the fruit can have a longer fresh-market shelf life. Takeda says fruit harvested by traditional over-the-row harvesters is bruised and becomes soft which can reduce shelf life.

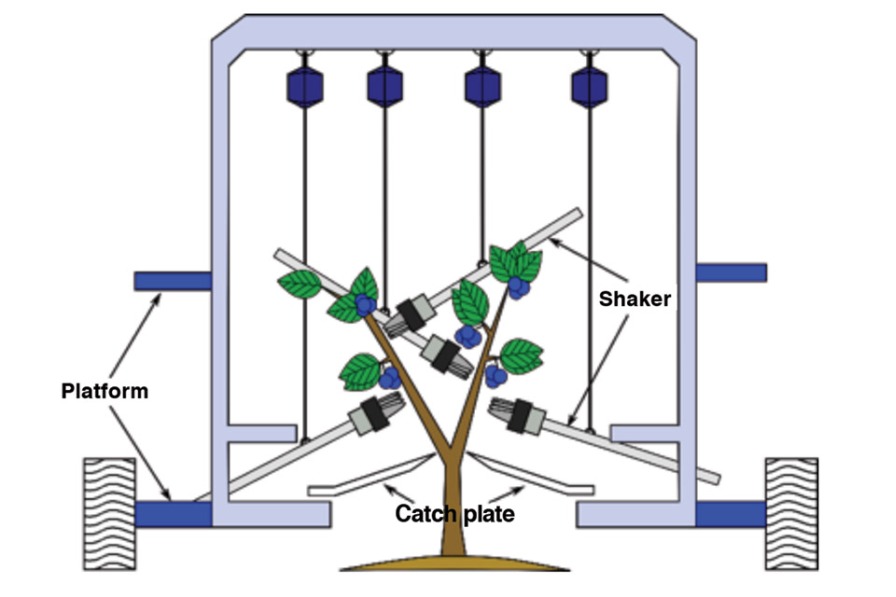

“Our research is concentrated in developing designs for fruit detachment equipment that can harvest ripe fruit more gently, designing fruit catching surfaces that will not bruise the fruit,” Takeda says. “Our approach to semi-mechanical harvesting is based on the integration of a self-propelled harvest platform with improved hand-held shakers and a novel berry catching system.”

He says the team is using the impact sensor to study how the shake and catch system impacts fruit so they can fine-tune the operating parameters and design features — vibration frequency, magnitude, and the shaker angle relative to the blueberry bush.

The Harvest Assist System

The team’s system is a moving platform pulled by a small tractor, or preferably self-propelled and self-steering — what he calls an “in-between” system. Workers stand on the platform with a shaker to “pick” ripe blueberries. The harvested fruit lands on soft catch plates and fruit collection surfaces and the conveyors transfer the fruit into lugs. With this system, the workers can focus on harvesting blueberries and let the machinery collect the harvested fruit and fill the lugs.

“In the last three years we used hand-held, air-powered shakers to remove fruit from the plant and a tractor-pulled fruit catching platform with modifications to reduce fruit bruising,” he says. “In 2017, we plan to have an agricultural equipment manufacturer build the project team a self-propelled, self-steering platform with a powered fruit-conveyance system and fruit-catching surface that will not bruise the fruit detached by semi-mechanical, hand-held shakers.”

Takeda says after research in the field this year and last, the team sees this new technology as quite promising. Workers do not need to make several steps — positioning, shaking, handling collection of the fruit, etc. He says the semi-automated harvest is 10- to 20 times faster than hand harvesting. The shakers used are tethered and counter-weighted on the system, which he says also helps reduce injuries and fatigue.

This easy harvester photographed at a demo in Oregon has been modified with tool-balancer as well as a softer fruit catching surface. It was towed by a small tractor. (Photo Credit: USDA-ARS)

Ergonomics Of Harvesting

Andris Freivalds, an industrial engineering professor with Penn State is leading the ergonomic analysis of this harvesting system. So far, Freivalds’ team of engineers has conducted physiological analysis of workers operating the shaker, including muscle activity and heart rate. Measurements of muscle strain indicated shaker weight and vibration were critical factors to consider for worker comfort.

The light-weight shakers caused less muscle strain in the back, shoulders, and forearms. In field studies, a tool-support balancer showed positive effects and a shock-absorbing pad reduced the vibration caused by the pneumatic system. The team plans to include the modifications of shock-absorbing pads on the handles, as well as tethering shakers to platforms.

“The harvest aid system that is tethered to a tool balancer will definitely reduce fatigue because workers do not need to hold up the shaker all the time,” he says.

Another modification is a new berry-catch plate to cut losses. However, the ultimate goal of this project is to create a system that is scale neutral — so it can be appealing to small growers as well as to large growers through increases in high-quality yields and worker efficiency.

“The performance of our new harvesting platform will be appealing to large and small growers alike. Its cost will be substantially lower than a regular over-the-row harvesters, which can currently cost as much as $200,000,” Takeda says.

Improvements Over Current Systems

The research conducted so far points toward a mechanical harvesting system that has high harvesting efficiency and at the same time delivers fruit with little or no mechanical damage. Further development of sensor technologies will be useful for improving both the harvesting and packingline efficiency and blueberry quality.

Takeda says current over-the-row harvest systems can cause losses of anywhere from 20% to 30% due to bruised fruit. Takeda’s co-principal investigator, Charlie Li of the University of Georgia, is developing a non-invasive approach to detecting damaged fruit. The team is using a near-infrared hyperspectral imaging system.

In preliminary research, the team has been able to detect the amount of bruised tissues in individual blueberry fruit. Li says he is optimistic that with further improvements in efficiency and the accuracy, it can be used for on-the-line sorting of bruised blueberries.