Why Digital Precision Means More Peaches From the Orchard

In my recent column, “Precision-Ready Peach Orchards Growing Into a Thing of Beauty,” I summarized some research over the past 10 years focusing on higher-density, labor-efficient peach orchard systems, specifically vigor-limiting rootstocks and “two-dimensional” or “planar” canopy training strategies.

In May, the 10th International Peach Symposium was held under the auspices of the International Society for Horticultural Science in Greece. Delayed a year due to COVID, this quadrennial gathering of the world’s top peach scientists addressed advances in genetics, production physiology, insect/disease control, and storage technologies.

Of particular note for peach growers was an increasing consensus that future production will require — you guessed it — high-density, labor-efficient production systems that can facilitate greater mechanization and digital precision management technologies. So, let’s break down some of those aspects I alluded to in March.

Our peach orchard systems research focuses on two fundamentals: 1) a multi-leader planar canopy structure like that for Upright Fruiting Offshoots (UFO) training, and 2) efficient and precise canopy vigor and crop load management like that for Super Slender Axe (SSA) pruning.

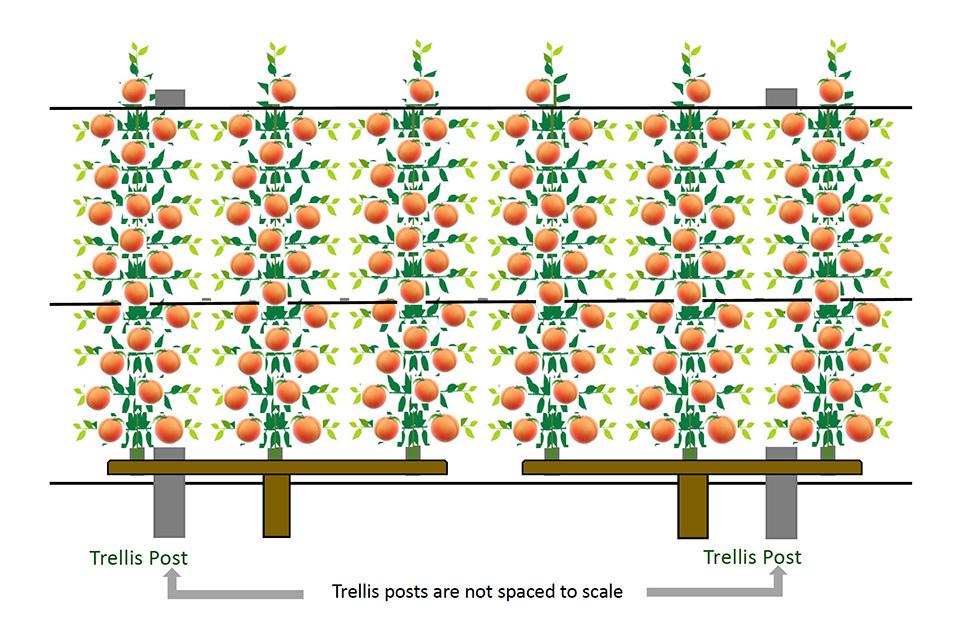

The goal for future orchard canopies will be to create a highly structured, narrow tree wall comprised of uniform, simplified, repeating canopy units having sufficient flower buds for a target yield, with sufficient leaves to provide target fruit quality, and sufficient new shoots to repeat these goals the next season.

Fig. A. Peach orchard systems in progress. The multiple (3 to 8 or more, depending on rootstock vigor) simplified, repeatable upright fruiting offshoots (or leaders) developed from a low, permanent trunk with UFO training and SSA pruning.

Graphic courtesy of Gregory Lang

UPRIGHT FRUITING OFFSHOOTS STRUCTURE

The foundation of UFO training is to develop multiple uniform upright fruiting offshoots (or mini-leaders) arising from a low, permanent trunk that resembles the cordons of a trellised grape vine (see Fig. A above). This has several important advantages.

For peach, we currently think offshoot spacing can be optimized at about 18 to 24 inches (50 to 62 centimeters). We use three trellis wires: the bottom for orienting the horizontal trunk cordons, the middle for stabilizing the growing offshoots, and the top for maintaining the vertical orientation against prevailing winds and the weight of crop loads. We complete the trellis matrix with twine every 18 to 24 inches, tied at each wire to precisely orient the upright leaders as they grow to maximize structural light interception.

The ability to vary the multiple leader number provides adaptable diffusion of vigor, meaning rootstocks suited to localized soil/climate conditions can be used, ranging from dwarfing to vigorous. Although tree spacing will vary proportionally to rootstock vigor, spacing of the upright offshoots is constant to assure maximum precise light interception by the planar canopy.

The vertical orientation of the upright offshoots (or steeply angled, in the case of a dual-plane V canopy) utilizes the tree’s natural growth and apical dominance for the canopy structure, quickly filling or re-filling vertical canopy space during development or if an upright is lost or renewed. With vertical growth, the initial formation of leaves and lateral fruiting shoots follows what is known as a Fibonacci pattern that evolved to capture light for photosynthesis as efficiently as possible.

By maintaining apical dominance and vigor diffusion, the lateral fruiting shoots that form tend to be moderate in vigor. This achieves more uniform light interception and distribution and helps maintain fruitfulness of the lower canopy as well as lower vigor in the top of the canopy (which can be problematic in single- and two-leader canopies unless dwarfing rootstocks are utilized).

SUPER SLENDER AXE PRUNING

The foundation of SSA pruning is to utilize severe annual pruning to achieve partial crop load management as well as contribute to vigor control and uniform light distribution throughout the vertical canopy.

Foremost is the goal to short-prune every fruiting lateral shoot so that, ultimately, only a single fruit is allowed to mature per lateral, eliminating decision variations to be made during hand (or eventually robotic) thinning. We have calculated that only 20 to 30 fruit per leader are needed to achieve commercially profitable yields, meaning the 20 to 30 necessary lateral fruiting branches are easily achievable.

We are studying the impact of leaving variable proportions of additional, non-fruiting lateral shoots to add additional efficient leaf area, as well as to create new fruiting sites for the next year. This also diffuses lateral shoot vigor to maintain shorter laterals that reduce the potential for shade as well as the incidence of water sprout growth. Stay tuned for more insights as these systems are refined further!