Why the Almond Industry Is on the Edge of a Revolution

University of California, Davis’ Dr. Patrick Brown, teaming with peers at the university and around the world, is working with growers, the Almond Board of California, advocacy groups, and others to bring about a revolution in the almond industry.

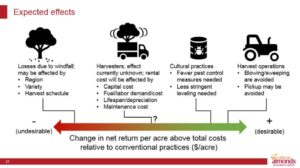

Dubbed “Advanced Harvest,” Brown points to a number of reasons he believes the new concept will become an industry standard in the next decade, including a commitment by the California almond community to reduce harvest dust by 50%, the potential for limits on the use of glyphosate, grower interest in improving soil and orchard health, the need to improve water and nutrient use efficiency, the desire to reduce disease and insect damage, and other profit-eating factors.

“Change of this magnitude will be difficult,” Brown says, “but given the challenges facing the industry, it is probably not a question of if, but only when.”

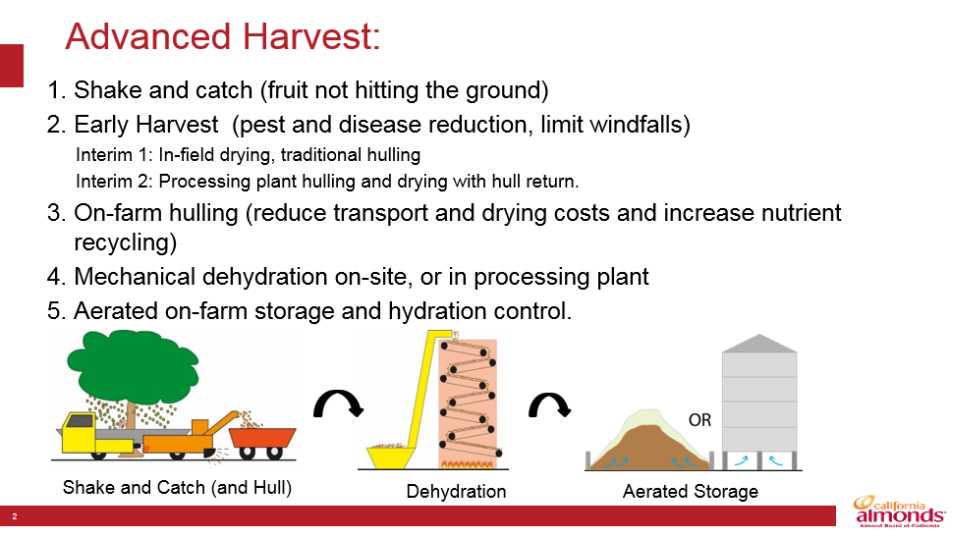

Advanced Harvest is being developed as a multifaceted approach to harvesting almonds combining a “shake and catch” off-ground system for collecting the nuts, an earlier harvest schedule than has been traditional, on-farm hulling, mechanized drying, either on-farm or in a dedicated drying facility, and aerated storage of the nuts.

As documented by Brown and others, while some specific aspects of the approach are still under study, Advanced Harvest shows promise of doing what it’s intended — improving public health even as higher profits are enjoyed by the farm. Goals include significantly reducing dust, substantially reducing both insect and disease damage to the crop, increasing public safety, and reducing the use of both fertilizers and certain insect control regimens.

Two essential keys to Advanced Harvest are single-pass, off-ground collection of the nuts shaken from the trees and an earlier harvest. Unlike most of today’s harvest, fruit never comes in contact with the orchard floor.

EARLY HARVEST A PLUS

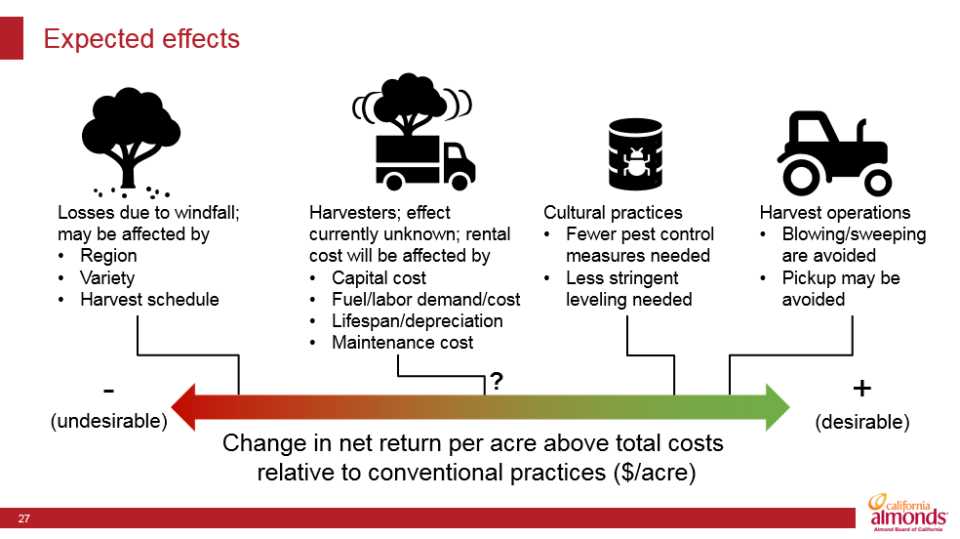

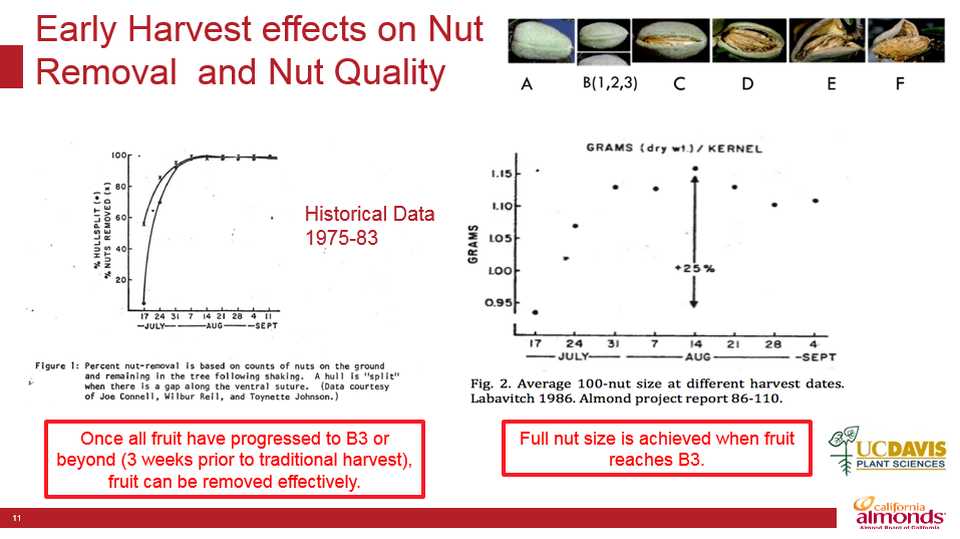

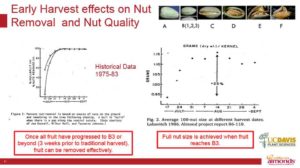

Regarding nut size, quality, and numbers, Brown presents compelling data supporting the potential efficacy of early harvest. First described in the mid-1980s and verified in 2017 and 2018, research shows little or no difference in nut size, quality, or removal efficiency if nuts are removed from the tree three weeks prior to traditional harvest dates. The issues surrounding windfalls, nuts that fall prior to harvest, and the place they play in recovery volumes is part of an on-going study by Brown and his colleagues to investigate the pros and cons of various Advanced Harvest permutations.

According to Brown, off-ground harvest and the earlier removal of almonds from the tree and the field provide some important and obvious, if not yet fully quantified, economic and food safety benefits. Having open, mature fruit in the tree and orchard for extended periods increases the potential for infestations by one of the primary pests, the naval orangeworm (NOW).

Besides reducing the opportunity for aflatoxin molds to establish themselves, Brown posits earlier harvest and prompt removal also puts the harvest ahead of the curve for most hull rot, a disease impacting not only present but future harvests. A significant reduction in hull rot is projected along with reductions in NOW and aflatoxins is a probable natural result of off-ground and early harvest. While entomologists and pathologists have suggested this approach is “very likely beneficial by reducing in-tree and on-ground nut damage and contamination,” he comments, “researchers and growers will still want to see the proof!”

JUST ONE PASS

Single-pass collection of the almonds in coordination with an early harvest also provides significant advantages, according to Brown. While some are so obvious as to seem intuitive, some seem likely but still need to be quantified. Obvious benefits include substantial reductions in dust, reductions in greenhouse gas emissions, and reduced harm to crop and trees due to harvest water stress, insects, and disease.

Single-pass collection means just that, the nuts are harvested with one pass through the orchard rather than the three, four, or five passes in a conventional harvest today. It means little soil disturbance, in stark contrast to conventional methods. Dust clouds, which years ago made Los Angeles smog on a bad day in the ’70s look good, have been reduced but remain a problem.

Dust reductions as the result of fewer passes with reduced ground disturbance can be taken as a given result of Advanced Harvest. An added benefit of not harvesting from the orchard floor is the freedom to use cover crops or other organic matter amendments to optimize tree and soil health.

Reducing greenhouse gas emissions is a matter of public policy achieved in Advanced Harvest scenarios by the elimination of several machinery passes through an orchard during harvest; an important public benefit is provided even as the orchardist is able to reduce fuel and machine expenses as the result of reduced machine usage.

QUESTIONS REMAIN

Less well understood are the details of how shake-and-catch harvest, on-farm hulling, mechanized drying — either on farm or in a dedicated drying facility — and aerated storage of the nuts will be achieved. However, the opportunities for innovation are significant. And an extensive series of on-going studies are underway to further refine knowledge about best approaches to each issue and to quantify benefits.

In the meantime, Brown says, orchardists preparing for the adoption of Advanced Harvest as the standard in the industry can plant orchards today with an eye to the future.

“Placing the tree crotch higher is likely advantageous, as is closer in-row planting and greater between row planting,” Brown advises. “This will accommodate the larger machines. Smaller cultivars or size-controlling rootstocks may also help.”

Brown firmly believes Advanced Harvest represents a revolution in the orchard in that, when fully developed and quantified as to benefit, nearly every aspect of conventional harvest as practiced today will change. The payoff, says Brown, will come in vastly reduced dust generation, significant reductions in insect and disease harm to the crop, improved orchard health, improved public health, reduced regulatory pressure, and increased grower profits.