What To Consider When Growing High Tunnel Sweet Cherries

In my May column on sweet cherries, the production limitation of fruit cracking was reviewed. One potential remedy to reduce the incidence of cracking is to grow cherries under protective covers, such as high tunnels, cable-and-pole tents, or retractable covering structures. Each covering option has strengths and weaknesses, as well as significant cost differentials. This month’s column will focus on high tunnel covering structures, with the other protective covering options to be addressed in future issues.

In my May column on sweet cherries, the production limitation of fruit cracking was reviewed. One potential remedy to reduce the incidence of cracking is to grow cherries under protective covers, such as high tunnels, cable-and-pole tents, or retractable covering structures. Each covering option has strengths and weaknesses, as well as significant cost differentials. This month’s column will focus on high tunnel covering structures, with the other protective covering options to be addressed in future issues.

What’s The Return On Investment

The first step if you are considering a cherry covering strategy is to examine the specific marketing opportunities and anticipated returns for your operation. What is the likelihood of crop damage from rain, and how extensive might the crop loss be? For example, preventing a crop loss of 30% twice every 10 years may not recover the structure investment costs; preventing a 75% crop loss two out of every five years, however, would likely provide a rapid return on your investment!

Furthermore, for such specialized orchard operations as pick-your-own, the ability to guarantee customers that they can pick tree-ripened cherries in any weather, even on that rainy weekend when they hoped to make a trip to your orchard/market, can be invaluable!

Beyond these rain-cracking issues, growers considering covering systems should investigate what other added values might be gained from investing in a covering system. Among the structures we have studied at Michigan State University since 2005, we have documented varying potentials for improved protection from spring frosts, better fruit set during cold rainy bloom periods, the capability to promote earlier ripening to supply market windows when prices are higher, larger fruits that can command premium prices, reductions in some diseases and insect pests (thus reduced pesticide use and costs), easier protection from birds (and deer and raccoons), and overall healthier trees.

Structures To Consider

Structures To Consider

The most common high tunnel structure for cherry orchards is the three-season, multi-bay, single-layer plastic tunnel (vs. the four-season, stand-alone single bay, double-layer plastic tunnel often used in year-round vegetable production). Multi-bay tunnels are generally less expensive than single bays per area covered. Three-season tunnels are left uncovered in the winter, as the structures are not engineered to withstand snow loads. Also, cherry trees need to be exposed to chilling winter conditions to satisfy the dormancy period of their life cycle, as well as to cold-acclimate adequately in sites that experience severe winter low temperatures, like Michigan.

Single-layer plastic covers provide excellent protection from fruit cracking caused by rain directly on the fruit. However, as noted in the May issue, cracking also can be caused by excessive soil water uptake, and we have documented fruit cracking as high as 60% from rainwater that flowed off the tunnels into soil near the root system of covered trees (this rain event caused 90% cracking in uncovered trees).

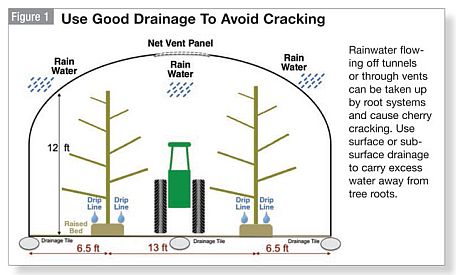

Therefore, it is highly recommended that surface or subsurface orchard drainage be modified wherever rainwater is diverted by the tunnel structure, generally along the tunnel leg rows. On sloped orchard sites, this may be accomplished with surface grading and plastic sheeting. On flat sites, subsurface drainage pipes and gravel-filled channels may be used to divert surface water and reduce infiltration near the tree root system (see Figure 1).

A relatively new development in high tunnel cherry production is the availability of plastic with a net panel located near the tunnel peak, to better vent excessive heat during ripening that can reduce fruit quality. If such net-paneled plastic is used, soil drainage also must be planned where rain falls through the netting (Figure 1). Planting trees on raised beds or berms also can reduce the potential for cracking due to excessive soil moisture, especially when dwarfing rootstocks are used (Figure 1).

Tree Development Under Structures

Tree Development Under Structures

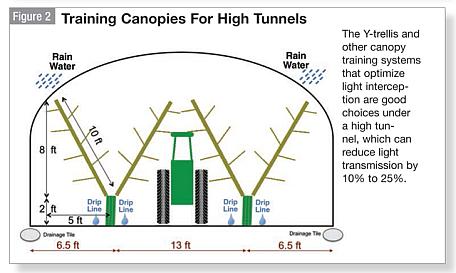

The final topic to discuss in this introduction to cherry covering systems is tree development under protective structures. The fixed plastic covering on high tunnels generally reduces light transmission by 10% to 25%, depending on the properties of the plastic, though light scattering (diffuse light) can be increased. This means that relatively narrow tree canopies will improve the distribution of adequate light for high-quality fruit production.

Furthermore, since the covering structure represents a significant capital investment, maximizing the light-interception area of the tree canopy will produce greater yields of uniformly-ripened fruit and return on investment. One such canopy training system for optimizing light interception under a high tunnel (with no peak ventilation panel) is the Y-trellising of a narrow canopy architecture like the upright fruiting offshoots (UFO) training system (Figure 2).

Further information about cherry training systems, such as the TSA and Y-UFO, will be forthcoming in an extension publication being developed jointly by Oregon State University, Michigan State University, and Washington State University. Short videos focused on various aspects of these systems also are viewable at GiselaCherry.com/Video.html, and additional information on training system and high tunnel research is available at HRT.MSU.edu/Greg-Lang and Cherries.MSU.edu.