Get in Gear Now for Agriculture’s Robotic Revolution

For Harvest CROO Robotics’ automated strawberry harvester, the picking wheel is the heart of technology with cameras to identify ripe berries and clamps to pick them.

Photo courtesy of Harvest CROO Robotics

While the immigration debate rages on in Washington, DC, with little chance for reform in sight, the uncertain labor picture growers have been dealing with doesn’t appear to be getting better anytime soon. And, even if a grand reform were to be reached, there are larger factors at play that suggest the situation will not improve in the future.

Gary Wishnatzki, Owner of Plant City, FL-based Wish Farms and Co-Founder of Harvest CROO Robotics, says there is a demographic shift that will drive agriculture to innovate and adopt robotics in the future to fill the labor void.

Why Robotics?

Wishnatzki says he began realizing the labor force was shrinking in the early 2000s when fewer people started showing up to the farm looking for work. That was a big change from the 1980s and 1990s when the labor force was flush and workers had to be turned away from the farm. Traditionally, he says, new arrivals to America have taken the harder labor jobs.

“It has always been the first generation of people who have come to this country who worked in agriculture and were willing to do the hard work that people who had been here a while didn’t want to do,” he says. “Once somebody has been here for a generation, they begin to move on to other jobs.”

Wish Farms has been very involved with sponsoring scholarship programs for the children of farmworkers, because Wishnatzki appreciates that these families want their children to have opportunities beyond picking strawberries.

Wish Farms has been very involved with sponsoring scholarship programs for the children of farmworkers, because Wishnatzki appreciates that these families want their children to have opportunities beyond picking strawberries.

“We have always depended on these new arrivals, but there are fewer of them now,” he says. “In fact, it now has reversed. In 2015, Pew Research published a paper showing there are more people going back to Mexico than coming into America.”

There are a number of factors coming into play to cause this trend, including an improving economy in Mexico. Falling fertility rates in Mexico also will impact labor availability. In the 1960s through the early 1970s, the fertility rate in Mexico was 6.7 (births per mother). The rate began dropping in the mid-1970s and had fallen to 2.1 by 2015.

“In the 1960s through 1980s, there was no opportunity in Mexico, so all of these people were flowing over the border looking for work,” Wishnatzki says. “That was why there was plenty of labor. You can argue border security has had some impact, but this is not about politics — it is simple demographics,” Wishnatzki says. “And, there are more opportunities and work in Mexico now, so there is not a reason for people to come here looking for work. With the fertility rate in Mexico at 2.1, which barely sustains the population, we know this trend is not going to reverse or change. It will get worse. And, what a lot of people don’t appreciate yet is Mexico will become a net-importer of labor in the near future. Mexico will be looking to other countries in South and Central America to import their workers.”

These changing demographics and the prospect of competing with Mexico for farm labor led Wishnatzki to the conclusion that robotic harvest and other tasks are the way of the future. He also believes Mexico will be looking for automation within 20 years because of the need to fill farm labor jobs there and a declining population willing to do the work.

Technological Wave

Wishnatzki says he co-founded Harvest CROO Robotics to develop a robot that harvests and packs ripe strawberries in the field. He is not alone in the belief that human labor will simply not be sufficient in the future. In fact, the growers who have invested in the robot’s development represent 60% of strawberry acreage in America.

The strawberry harvesting robot, like the many other technologies in development, is being enabled by rapidly advancing computing power.

“The things we are doing right now were not possible even five years ago,” Wishnatzki says. “The video processors we are using are capable of analyzing 30 gigabytes of data per second, which is mind boggling. This allows us to take high-resolution images to identify ripe berries on the plant in a very short time.”

Dr. Rex Lee, Founder of Pyramid Imaging, has been working with Harvest CROO to develop the machine vision side of the robot. Wishnatzki says one of his favorite quotes comes from Lee in response to those who said it was impossible to build a strawberry-harvesting robot.

“If a solution requires laws of physics to be broken, then it is impossible,” Lee says. “Otherwise, it is just an engineering problem and nothing is impossible.”

That is just what the dozen engineers working on the strawberry robot are doing right now — working out the kinks to get the machine field-ready and real-world operational. The heart of the machine is its picking wheel. Each wheel is equipped with a stereo vision camera and gives every berry on the plant a ripeness value to determine if it is ready for picking. If ripe, a mechanical clamp will pick the berry and drop it into a cup before moving it to the platform level.

The robot also will punch holes in beds before planting transplants. This is done using sub-inch accuracy GPS. When the picking wheels come through later in the season for harvest, the GPS will allow the machine to detect where the exact centers of the plants are.

Each machine will be equipped with 16 picking wheels on an autonomously driven platform that will straddle four rows of berries. When fully operational, the goal is to have each machine capable of harvesting 8 acres per day, covering 25 acres on a three-day cycle.

“If a grower had a larger field, like a 25-acre block, he might consider putting three machines in the field and pick it over a one-day period rather than three days,” Wishnatzki says. “There are a lot of different considerations we are looking at in developing the system. But, our goal is to have one machine replace the need for about 25 to 30 workers.”

Wishnatzki also expects other benefits from the robot like more precise packing to avoid overpacking, resulting in more units.

“We will be packing these strawberries on the platform using the robots and weighing every package,” he says. “Currently, we are packing berries in the field visually, so often we are overpacking quite a bit. The machine will allow us to weigh and eliminate the 10% to 20% overpacking we see with hand harvest and get a lot more units.”

Next season, Harvest CROO will have robots punching holes for planting in both Florida and California and further harvest testing in both states.

When the technology is ready for commercial use, it will be offered as a harvest service. Growers won’t have to worry about investing in the machines, and trained technicians will operate the complex equipment.

Precision Vision

The ag-tech revolution is happening across Florida via private and public research and development. Nathan Boyd, an Associate Professor of weed science with UF/IFAS, is spearheading an effort to utilize machine vision and artificial intelligence to identify and control weeds. Arnold Schumann, a Professor of soil and water science, has worked closely on the project as well This technology is more focused on reducing inputs rather than labor savings.

The herbicide applicator being developed by Nathan Boyd and his UF/IFAS team will use machine vision to target only weeds.

Photo by Nathan Boyd

One project involves preemergence herbicides being applied to the top of beds after plastic is laid to cover them. Weeds, with the exception of nutsedge, can only emerge through the holes punched in the plastic where transplants are placed.

“Growers typically apply herbicides immediately before laying the plastic mulch,” Boyd says. “We have developed a hole-punch applicator that sprays herbicides in the holes as you punch them. As you move through the field with a standard hole punch, the sensors detect where the hole is and apply herbicides in the hole. This can reduce preemergence herbicide use by 88% to 90%.”

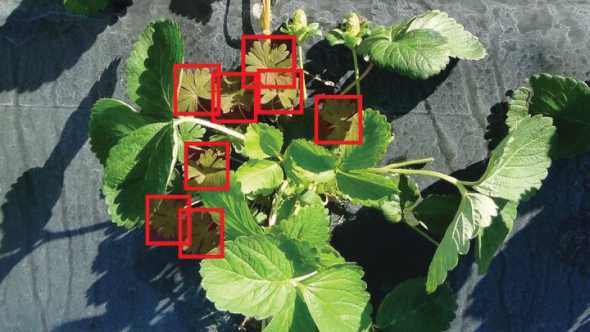

As for nutsedge, the grand nemesis, of plastic mulch crops, Boyd is developing technology aimed at controlling the weed. The technology uses machine vision and an artificial neural network to detect nutsedge that has punctured the plastic and apply herbicide only where the weed occurs.

Boyd says the projects he is developing should be available to growers in a few short years because the advancement of technology and computing power is happening at such a fast pace.

Consider the Cell Phone

Wishnatzki likes to use the analogy of cell phones to help explain the future of robotics and other technologies.

“When people ask me where we are with this technology, I tell them to think about the earliest cell phones,” he says. “That is where we are today with our robot technology — at the very beginning of what we will be able to do.”

He adds people only wanted to make calls with the early cell phones and could have never imagined all that can be done with today’s smartphones. He believes that will be the case with the Harvest CROO machine.

“Right now, we just want it to pick strawberries,” he says. “We believe we can add other tasks to the machine platform. We have already thought of a few of those things, and I am sure there are things we have not even dreamed of yet that will be possible in the future.”

The engineering team is looking at using the robot to scout for pest and disease hotspots in fields, pruning runners, improved bloom forecasting, and hydrocooling in the field.

“We are working with Natalia Peres, an Associate Professor of stawberry pathology with UF/IFAS, to look at placing ultraviolet C (UVC) lighting on the platform to possibly kill off different fungi and mildews on plants while it makes harvest runs,” Wishnatzki says. “Not only could the UVC illuminate the plants as it works during the night, it also could help reduce some of these fungi and even have some food safety benefits by killing potential foodborne illness pathogens on plants and fruit.”

Boyd agrees we are only at the beginning of seeing the benefits ag-tech will bring to farming.

“In the next five to 10 years, precision ag will rely more and more on autonomous vehicles and robotics,” he says. “Vegetable production will shift from a high-labor industry to a highly technical industry, requiring well-trained personnel to operate and maintain the specialized equipment. We are in the early stages of a complete transformation of agriculture. This transition is exciting, but it won’t occur without some upheaval. A move toward robotics and autonomous vehicles with a much smaller labor force will impact entire communities.”

All Aboard the Tech Train

Innovations in agricultural technology are being developed all over the country, and the tech giants are suddenly taking note of farming. Venture capital dollars are flowing to advance this wave of machines, artificial intelligence, and data management that will impact agriculture.

Even leading retailers like Walmart are getting into the game. CBI Insights recently released a report that Walmart has applied for a range of patents using drones to automate farming. The patents propose using drones and machine vision to identify pests attacking crops, monitor crop damage, and spray pesticides on the crops. One of the Walmart patents also utilizes drones to help pollinate crops.