Why Biodegradable Plastic Mulch is Trending with Berry Growers

Plastic biodegradable mulches can be applied with standard mulch application equipment.

Photo by Lisa DeVetter

Plastics are abundant in our everyday life because of their convenience, utility, and low costs. Plastic use in specialty crop production is no exception. From a berry production standpoint, plastics are essential, comprising drip tape, row covers, tarps, mulch, and more. Overall, we use a lot of plastics in berry production and benefit from the properties that plastic provides.

The utility and widespread use of plastics in agriculture also poses a problem ― plastics don’t go away. In fact, it may take more than 300 years for polyethylene plastic film to decompose in soil, and that process can form environmentally harmful byproducts. The global community has recognized plastic pollution and waste management as an important environmental issue.

While much of the focus in the media has been on plastic waste in the marine environment, few recognize that most of the microplastics found in the ocean come from plastics that have been disposed of on land and transported into waterways and marine systems. There is also mounting concern about plastics in terrestrial systems and impacts on soil health.

Agriculture has a role in contributing to plastic waste generation and pollution when mismanaged. However, not using plastics is a tall order. Approximately one billion pounds of plastics are used in agriculture annually, and most of this is for single-use applications. Mulches rank third in terms of amount of plastics used in agriculture, and this material is typically disposed of by being burned, buried, stockpiled, or tossed in a landfill. None of these options are very sustainable and don’t alleviate the problem of plastics in the environment. However, biodegradable plastic mulches (BDMs) may be a tool that growers could use to reduce plastic waste generation while still capitalizing on the benefits provided by plastic mulch.

BDMs have been around since the 1990s and are engineered to function like standard plastic mulch except for end-of-life management. Rather than pull BDMs from the field and dispose of them off-site, BDMs are designed to be tilled, or disked, into the soil. Soil microorganisms then biodegrade the mulch by using carbon present in the mulch for their metabolism, leaving no plastic fragments in the soil.

While BDMs sound like a great alternative to standard plastic mulches, there are some factors to be aware of. First are the imposter BDMs. Examples include oxo-degradable, oxo-biodegradable, and photodegradable mulches. These mulches are sometimes erroneously sold as biodegradable but are actually standard, plastic polymers with additives incorporated that cause fragmentation after exposure to oxygen, light, and/or heat. Fragmentation is a physiochemical process, not biological, and there is no breakdown from the action of microorganisms in the soil. Thus, oxo-films leave plastic fragments in soil and contribute to plastic waste generation.

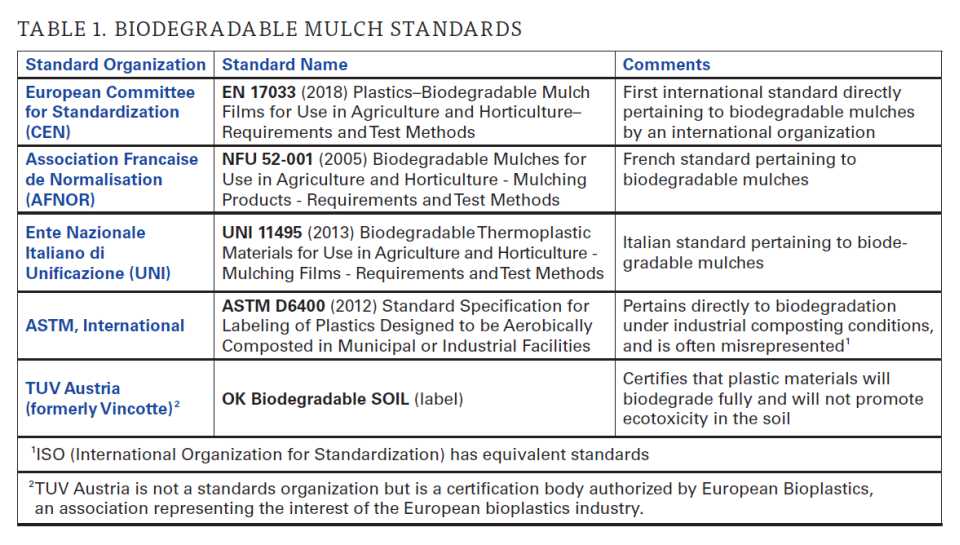

To distinguish a biodegradable from a non-biodegradable mulch film, standards are in place and should be considered. Examples of standards include EN 17033 and ASTM D6400. These standards ensure >90% biodegradation within a period of two years or less under composting or soil conditions. Always check or ask about biodegradability standards when considering use of a BDM to ensure product integrity and quality.

Chart source: Dentzman and Hayes, 2019

Commercially available BDMs do have some limitations. First, no commercially available plastic BDM meets the requirements for use in organic agriculture. The National Organic Program added bio-based BDMs to their list of allowable substances in 2017, but the rule requires products to be 100% bio-based and to be produced without excluded methods. Currently available commercial BDMs are only about 20% bio-based. Furthermore, genetically modified organisms are used to economically produce the biopolymers, and this is an excluded method for organic agriculture. While plastic BDMs cannot be used in organic production, some paper BDMs are permitted.

Another substantial barrier for berry production is the use of BDMs during soil fumigation. Many berry production systems depend on plastic tarps to retain fumigants in the soil and reduce buffer zones. These tarps then may function as a mulch after the fumigant reentry interval has expired and it’s safe to plant. BDMs are not tarps and should not be applied during the fumigation operation, as it’s unclear how fumigants and BDMs will interact and impact the film’s integrity.

Despite these barriers, BDMs are a promising technology. A substantial amount of research has been done to show they can be an economical and viable alternative in vegetable production systems. Further testing in berry crops across diverse production systems and environments is required, but they show potential as a tool to replace standard plastic mulches.

For more information on biodegradable plastic mulches, visit: https://smallfruits.wsu.edu/ and www.biodegradablemulch.org.