High-Tech Building Boom In The Pacific Northwest

The new Greefa unit at Stemilt is nearly the length of a football field. “It just keeps going and going,” says General Manager Jay Fulbright. (Photo courtesy of Stemilt)

The Pacific Northwest hosted a lot of foreign visitors prior to this year’s harvest as new sizers and packing lines were installed by equipment companies from all over the world.

For example, one of the largest tree fruit growers in North America, Stemilt Growers, unveiled one of world’s largest apple sizers.

The Wenatchee, WA, company recently installed a new, high-tech apple line from Netherlands at its Olds Station facility. It features the latest generation of external defect sorting (iQs IV) and internal quality sorting (iFA GeoSort) from Greefa and a long, gentle sizer with 79 drop points to pack apples gently and with great consistency.

“We’re excited about the addition of our new Greefa commit-to-pack line at Olds Station,” says Jay Fulbright, vice president of operations and special projects at Stemilt. “The line relies on electronic, or optic, sizing and defect sorting technology to reduce manual sorting of fruit and human error. The technology is able to efficiently and gently size and sort apples and will help us deliver great consistency in every box.”

Starting From Scratch

Stemilt’s operations team led the construction of the new line, which began by completely deconstructing the existing commit-to-pack line. Starting with a blank slate allowed for the installation of the long Greefa sizer – which is nearly the length of a football field.

“It just keeps going and going,” Fulbright says. “The benefit of having one of the longest apple sizers in the world is having so many drop points for the fruit. We have the flexibility to pack multiple sizes and grades and also reduce the number of touches to the fruit, which is important in maintaining a high quality pack.”

The new apple line uses similar technology as the electronic cherry packing lines in which Stemilt has recently invested heavily. Apples move along the Greefa sizer through the “brains” of the line, where HD cameras rapidly take up to 60 images of each piece of fruit while it rotates.

The images are analyzed by computer software and the apple is accurately sorted according to its size, color, and internal and external quality or defects. Apples that don’t meet standards are rerouted to a downgrade sizer and additional sorting, while apples that continue down the line are packed into trays or bags.

Using Greefa’s iFA GeoSort grader, Stemilt can get an accurate reading on the internal characteristics and Brix value of each apple. The technology easily identifies and sorts out fruit with heavy water core and internal browning, Fulbright notes.

The line uses iQs IV external defect sorting technology to look at the outside of the apple. It recognizes and removes the stem and calyx ends of the fruit from the results, and allows high resolution cameras to pinpoint even the smallest external defects, including russet, hail, and bruising.

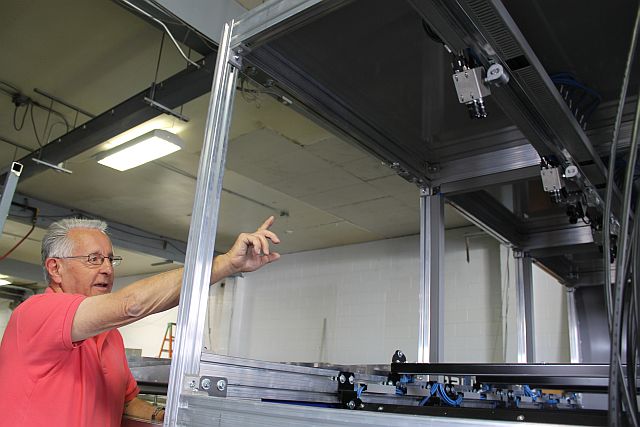

Apple King’s Ray Keller points out a few of the 32 cameras on his new Gran Torino unit from Elisam, which photographs each apple an average of 10 times. (Photo credit: David Eddy)

Apple Of His Eye

Using optics to sort apples is not new technology, but the ability to sort for external color and do it well is relatively new, Fulbright says.

“Consumers buy fruit with their eyes and the rise and popularity in bi-colored apples has created the need for us to do a better color sorting job,” he says. “Greefa’s grading technology gives us a 3D look at the apple. The multitude of images the software can analyze results in accurate sorting,” he adds.

Stemilt will use the new Greefa apple line primarily for conventional apples, while the company’s neighboring Euclid Street facility has a dedicated organic apple line. The Euclid Street line was also recently equipped with a defect sorter.

“The addition at Euclid and the new line at Olds make it possible for us to sort all of our apples electronically,” Fulbright says. “We can reduce labor costs and simultaneously deliver a consistent, high-quality pack. This helps in our overall goal of improving the consumer experience, building demand for our fruits, and delivering greater returns to our growers.”

Now That’s Italian

Meanwhile, down in Yakima, WA, another longtime grower/packer/ shipper, Apple King, has also installed state-of-the-art equipment. The Elisam Gran Torino can grade apples – as well as a whole host of other fruits and vegetables – for weight, size, color, and quality, both external and internal.

The Gran Torino is available with a number of lines, from two to eight, though Apple King opted for the highest volume model, says co-owner Ray Keller. He says he chose the company because they’ve worked with the owner before and utilized the company’s software for the past eight years.

The machine is extraordinarily thorough, Keller says. Each of the eight lines has four cameras, for a total of 32. With that many cameras, Apple King is able to photograph each apple an average of 10 times. What’s amazing about that, Keller says, is that all those photos are taken despite the machine’s extreme speed.

“We’re running the fruit through at eight to ten cups per second,” he says, “though that’s not untypical in the industry.”

Easy Does It

Perhaps more impressive than the speed with which the Gran Torino processes fruit is the gentle way it goes about it, Keller says. It utilizes cups to transfer the apples so there’s no dropping.

“Some people have to let Goldens and Honeycrisps – which bruise easily – let bruises go away in storage for four to five days,” he says. “We’re not getting that with this unit; we’re able to ship right away.”

The combination of speed and the velvet touch have attracted the attention of other grower/packer/shippers, Keller says, who doesn’t see the industry’s building boom end any time soon.

“Everything about it is well put together, and everybody who has looked at it likes it,” he says. “A few other growers are getting quotes.”

Click here see a video of Apple King’s Gran Torino in action.