Biocontrol Ideas for Vegetable Production

A number of great speakers offered practical tips for vegetable growers during the 2-hour breakout focusing on vegetable production at Biocontrols USA Conference & Expo 2022.

Here’s a sampling of what we learned.

Do’s and Don’ts of Tank Mixing

To get the best results from tank mixing your biocontrols, says Rob Gibson, Global Portfolio Manager, Certis Biologicals, consider all the elements.

Take water. pH can impact microbes efficacy, as can temperature, and mineral content. If you’re mixing your biologicals with fertilizers, 99 times out of 100 there will be no issues. When there are, they’re likely to be related to pH, Gibson says.

While most chemistries can mix together, there are some that will put your biologicals at risk. Copper is a good example of an organic control that can wreak havoc on a good biological control.

Gibson’s advice boiled down to five steps:

- Check the pesticide label for tank-mix recommendations and note any inhibitory effects

- If the mix is not well-known and label recommendations are vague or non-existent, perform a jar test prior to spraying

- Tank mix all pesticides properly and according to labels

- Double check equipment and filters

- Contact a biopesticides specialist with questions or needed confirmation

Is that a Pest? Or a Beneficial?

Grimmway Farms‘ Kim Horton gave a tutorial on how to tell the difference between the bugs you want and the ones you don’t.

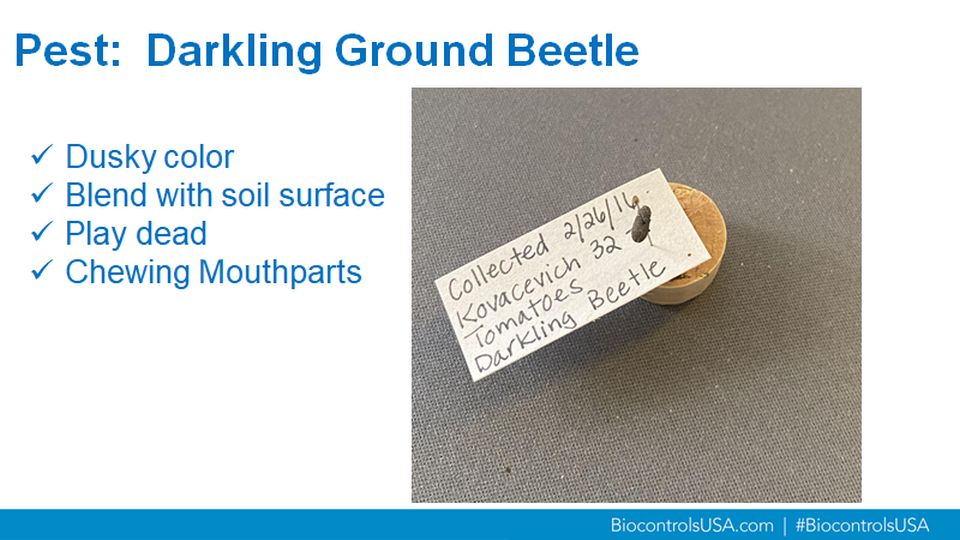

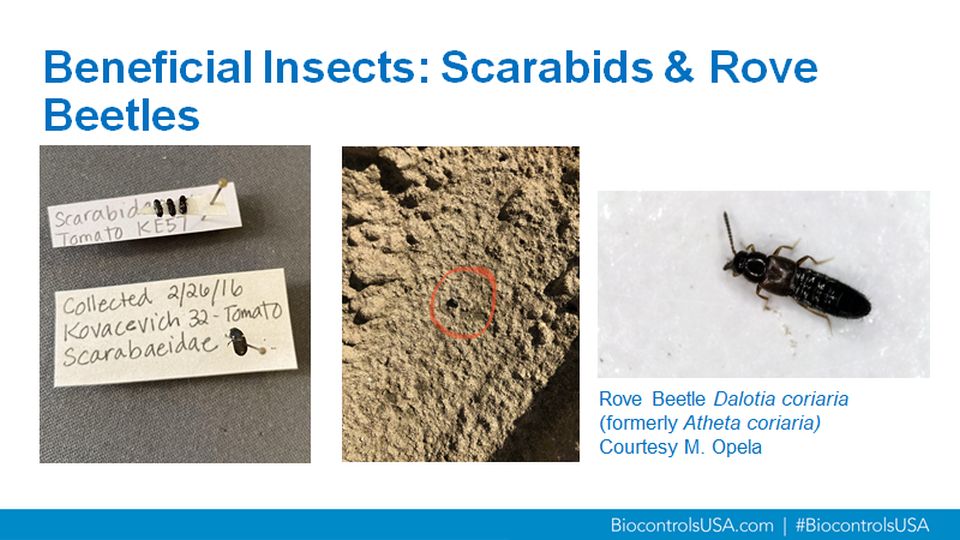

Horton provided photos and tips on how to spot the difference. Take, for example, the pest darkling ground beetle vs. scarabids and rove beetles (beneficials).

Darkling ground beetles are dusky and can blend with the soil surfaces. They also play dead when handled.

In contract, scarabs are shiny and feed on manure, fungi, or carrion. Rove beetles are also shiny and feed on root maggot eggs and larvae, mites, small soil insects, and insect eggs. They tend to hold the of the abdomen up.

Horton also compared common worm/caterpillar pests and their beneficial counterparts, as well as seedcorn maggots and nuisance flies with beneficial hunter flies and parasitic wasps.

In contrast with the pest darkling ground beetles, beneficial scarabs and rove beetles are shiny. Unmarked photos are all by Kim Horton.

The Whole Systems Approach

In agriculture, we tend to focus on each challenge separately. A crop’s need for pest control and irrigation makes it easy to take a myopic approach.

But agriculture exists within a broader ecosystem, says Wilbur Ellis‘ Gina Colfer. And the more growers can play into that larger system, the end result tends to benefit both grower and the environment.

“It encompasses a broad definition, but I want to keep it focused on improving soil and plant health, increasing biodiversity (both above and below ground), and incorporate a sound and validated IPM program within a system that can document the changes and, hopefully, improvements for future generations,” she says.

Colfer outlined four main ways a whole systems approach works.

- Soil health. Fertility program aimed at building soil microbiome while improving fertilizer plant uptake efficiencies to reduce nitrogen and phosphorus inputs. Also, using cover crops with proper timing and species selection for optimum soil and crop response.

- Support beneficials. Insectary habitat for optimum viability of beneficial biocontrol agents to minimize the impacts of insect pests. Determine best habitat and timing for the crop and situation. Increase diversity on the farm.

- Embrace IPM. Plant protection program that fits within the system that has been created. Use best methods and materials that are proven. Look at timing, rate, coverage, and chemistries to determine the best IPM approach with this system.

- Look at the full picture. Document sustainability practices and programs that could include reduced input use, runoff, and leaching mitigations, rodent management techniques, food safety metrics, IPM, and ag orders compliance.