Where to See the Future of Fruit Production Right Now

Reza Ehsani has been on a mission ever since he received a Ph.D. in Agricultural Engineering from the University of California, Davis, way back in 2000, when he was among the first students trained in precision agriculture.

After that he worked in Ohio where he taught how precision agriculture technology could be applied to row crops such as corn and soybeans. But his chief interest in specialty crops eventually led him to take a post at the University of Florida, where he focused on citrus, tomato, and strawberries.

Two years ago, he moved to California and started working as a Professor of Mechanical Engineering at the University of California, Merced. It is the newest campus in the UC system, and the only one in the San Joaquin Valley — one of the richest specialty crop regions in the world.

His research concentrates on system integration and applied research in developing advanced technologies for production and postharvest of high-value crops to increase the profitability and sustainability of agriculture production systems.

His research concentrates on system integration and applied research in developing advanced technologies for production and postharvest of high-value crops to increase the profitability and sustainability of agriculture production systems.

He has worked on developing sensors and data analysis techniques for early disease and stress detection of different crops as well as sensor systems for yield mapping and yield estimation. He is particularly interested in yield estimation, as it can have a direct bearing on growers’ profits.

“For high-value crops, yield estimation is very valuable,” he says. “For example, for strawberries, if you know what your yield will be next week, you will know how many pickers you will need.”

Ehsani recently gave a tour of his lab, which is located on the former Castle Air Force Base in Atwater, CA. Here’s a look at the projects he’s working on.

Photo by David Eddy

SMART CAMERA

Ehsani is working with postdoc and “right-hand man” Arash Toudeshki on a smart camera that can be programmed to detect a given object. The camera can distinguish the shape and color of a piece of fruit and can identify substandard fruits. It can be used for both sorting fresh fruit and fruit intended for processing.

“The camera can be programmed to detect a pistachio with the desired characteristics, for example,” he says.

But perhaps the greatest value of the smart camera, Ehsani says, is it can be used to estimate yields. You take a picture of a tree, and you can extrapolate the total yield based on what the camera sees by comparing the pictures with actual yields. You have to harvest several trees and then compare the number actually counted with the yields from the other trees to calibrate the camera.

This is nothing ground-breaking, Ehsani says, but it is a cheap, rugged, affordable camera that can be installed on a tractor. He estimates that when manufactured, the cost to growers would be no more than a couple hundred dollars.

“In the near future, we will look into incorporating the camera into a harvesting robot,” he says.

The same type of camera used here can be used on a processing line for sorting fruits and nuts. Current sorters are generally designed for large packinghouses and are not affordable to small growers.

“What we are trying to do here is to develop an in-field sorting machine for smaller growers,” says Ehsani. “You can pack it yourself if not a huge producer.”

Growers will be able to program the unit for different crops, “teaching” the camera what you want and what you don’t want.

Senior Laboratory Technician Joseph Trotochaud is working on the next step in the sorting system initiated by the smart camera. The fruit go under the camera, and after going under, the fruit is sorted into rows.

“Separating fruits into rows makes removal of unwanted fruit easier,” says Ehsani. “Then we will use these actuators to separate the fruit.”

Photo by David Eddy

MOISTURE SENSOR

These devices can detect water stress in trees. The larger one, on the left in the picture above, is just a year old but is already out of date, says Ehsani (pictured above, left), in that the information it gathers is stored on a flash card. On the right is the newer version, which is not only more compact, it sends information to the Cloud.

“You can get real-time access to data. You don’t have to travel to the field to get access to the flash card,” he says.

The new unit requires less power. It is also cheaper and should be available to growers for a couple hundred dollars.

“For smaller growers to be able to use it,” he says, “we have to keep costs down.”

Photo by David Eddy

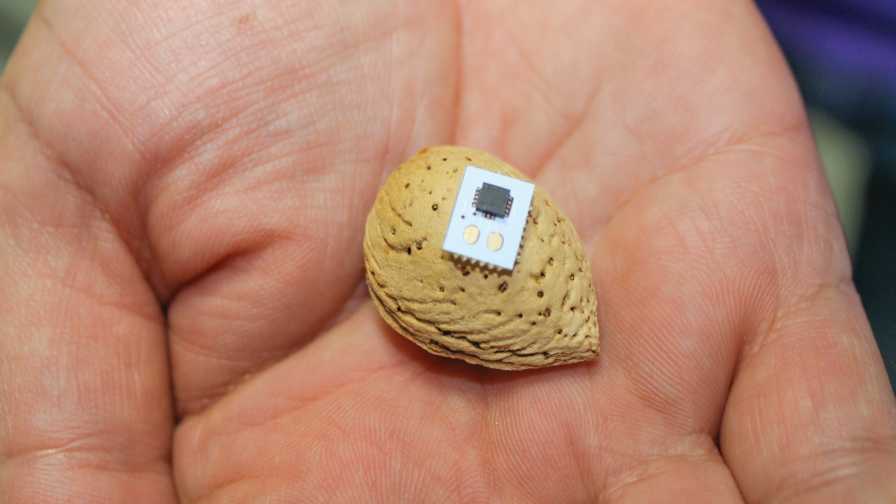

FORCE SENSOR

This tiny sensor is designed to make harvesting more efficient, cutting costs. It works by measuring the relative force that machine-harvested fruits and nuts feel during harvest, determining exactly how much force is necessary. Right now they are working on olives, but it can be used for crops such as almonds, as pictured here.

“It will help us improve existing mechanical harvesting machines and make the new generation of harvesters much smarter,” says Ehsani.

In the future, an operator can shake a tree based on the right amount of shaking for that individual tree, instead of the current practice of shaking every tree at the same frequency. The idea is based on the premise not all trees are the same, and each tree needs a certain level of shaking.

“Currently, shaking frequency and duration of shaking trees are based on operator’s decision, but they generally don’t change approach from tree to tree,” he says. “Let’s get that decision out of the operator’s hands and make it automatically controlled. This will help us develop the next generation of harvesters.”

Ehsani says they will put 30 sensor units on a single tree. The sensors have to be throughout the canopy, as not all fruits on a given tree require the same amount of force.

“We’re finding out what shaking force and which shaking pattern works best,” he says. “That way we can optimize the shaker.”

It’s tricky because the sensing unit has to be small enough that the weight of it has to be much less than fruit to get correct measurement. The current unit weighs just 130 milligrams. Ehsani and company also have a larger version of the sensor that is used on the branches.

Photo by David Eddy

TERAHERTZ TECH

Ehsani and food scientist Leili Afsah Hejri, who has a background in microbiology, have embarked on this project to sort pistachios at the request of the surrounding community, where many pistachio growers and processors are located.

The key to terahertz technology is that it can evaluate the nuts without destroying them, as is done with current technology. Terahertz technology, like an X-ray, can see through the fruit. The technology is currently used in other industries such as the pharmaceutical and medical industries, but Ehsani believes it has a lot of potential in the agricultural food industry.

“Nondestruction is the key,” he says. “We don’t do anything to the samples, we just observe them.”

The goal is to detect and eliminate food safety hazards in fruits and nuts, such as insect damage and aflatoxin.

“Right now, we are just beginning to figure out new applications and limitations, as well as the working parameters of this sensor,” he says. “This unit is mainly for us to evaluate; it’s not what a commercial unit would look like.”

One added benefit is that the grower can learn the precise moisture content of the fruit, which indicates maturity level. Terahertz technology is a very useful tool to detect bruising in fruits.

“The producer will be able to know exactly the moisture content of the fruit as well as any damages and defects,” Afsah-Hejri says, “enabling management decisions.”

Using this technology, shells can easily be differentiated from kernels and insect-damaged kernels. Different products can be classified based on their moisture content. Using terahertz technology in nut processing plants will enable processors to eliminate foreign materials and unwanted nuts without going through additional handpicking process.

“What we are trying to do here is to optimize the method and develop a quick image processing program to detect and eliminate unwanted nuts at the speed of the processing line,” says Ehsani.

Photo by David Eddy

BERRY ROBOT

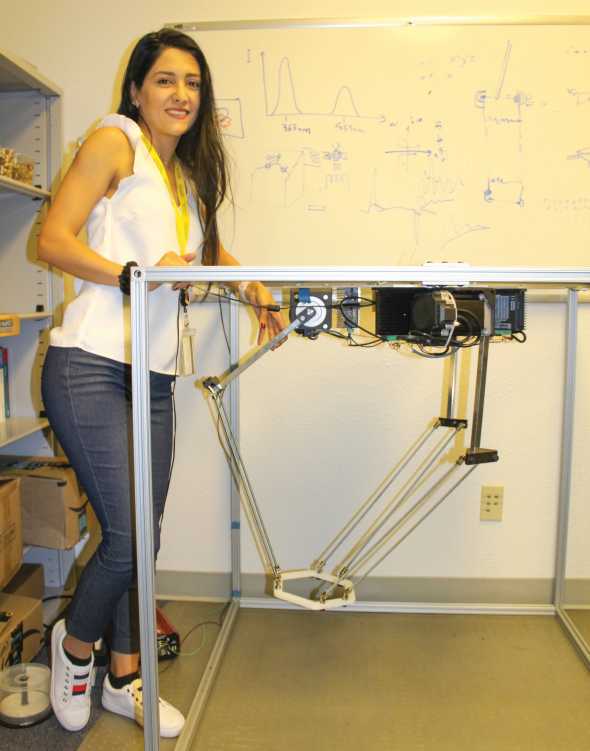

This project, a robotic strawberry harvester, is obviously just off the drawing board. Akram Gholami Pareh, a Ph.D. student in Ehsani’s lab, holds her part of the project — a robotic harvesting arm.

“Imagine this on four wheels in the field,” says Ehsani. “It’s a small unit designed for use by the smaller-acreage grower.”

The four-year project was launched in conjunction with the University of Central Florida and Washington State University. It was made possible by a $1.1 million grant awarded by the National Science Foundation’s National Robotics Initiative. The study is titled “Distributed Co-robots for Strawberry Harvesting” and will explore the possibilities and benefits of people and robots picking fruit together.

Ehsani says he has already developed a mechanical means of gentle fruit removal for other crops in the past and will apply that technology to the strawberry project.

“The human hand is particularly challenging to mimic in a machine, and strawberries are a very sensitive fruit; this project will test several robotic arms,” he says.

Photo by David Eddy

ALMOND HARVESTER

This just-launched project, to make almond harvesting more efficient, is funded by the Almond Board of California. Currently, after shaking the nuts from the tree, growers sweep the nuts into rows, and then pick them up.

“We want to see if we can combine the two steps into one pass, sweeping and picking up, while at the same time reducing dust,” he says. “It would also reduce the amount of fuel used, as well as the necessary labor.”

This working prototype is mounted on a tractor; Ehsani says the final version will be self-propelled.