Wisdom on What It Takes To Grow Amazing Watermelons

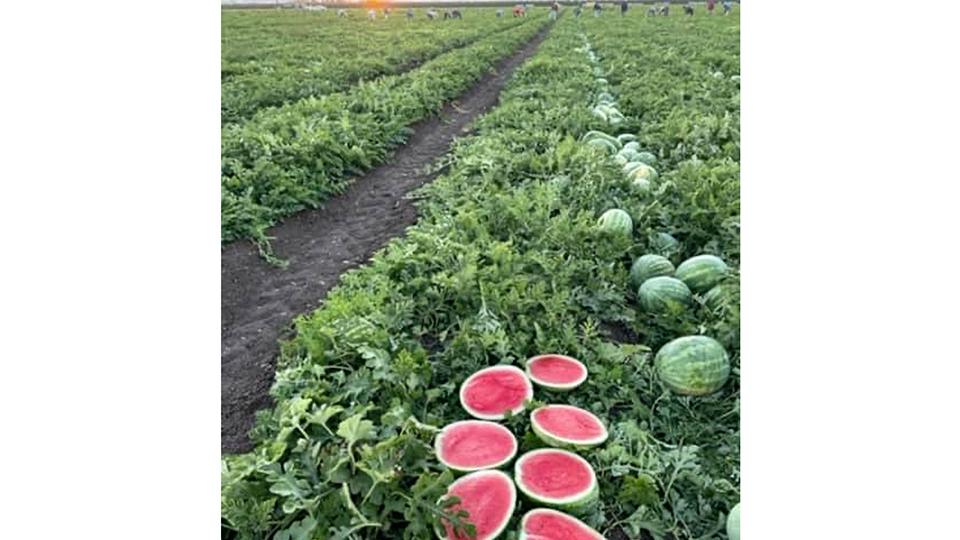

Those living and working in California’s Central Valley know Van Groningen & Sons for their watermelons. Even though they grow other crops at the same volume or higher, namely almonds and pumpkin.

With its level of expertise in watermelon production, Van Groningen & Sons and its Pest Control Adviser, Andrew Zanotto, have a wealth of knowledge to share. Here are a few of their secrets.

A Love for Fresh Fields

Since watermelons are so vulnerable to disease, Van Groningen & Sons’ favorite prevention is to steadily expand the operation’s acreage and plant on the new land.

“We try to put our watermelons on our freshest ground,” Zanotto says.

Orchards and vineyards dominate the Central Valley, and recent market price volatility has spurred some nearby orchards to rip out trees and sell or lease the land.

“We’ll develop it and lease it out for a few years. That first year is mainly going to be our water-melons,” he says.

It’s not foolproof, of course. This year, Zanotto planned to use former walnut grove acreage, which had never grown cucurbits, for its entire watermelon production — devoting about 1,000 acres to watermelons (800 regular and 200 minis).

Then the rivers of storms marched across the Central Valley prior to and during planting season. This ended the drought for now, thankfully. But several soggy fields couldn’t handle the heavy equipment.

Finding fields dry enough to get into became a higher priority than land with no prior watermelon production.

Fresh land won’t always be available. When planting in fields that previously had watermelon, Van Groningen & Sons rotates crops so there is at least a four-year gap between watermelon plantings. Its pumpkin crops typically go in the year following watermelon.

All In on Grafting

One powerful disease-fighting tool Van Groningen & Sons recently adopted is switching to grafted plants. All its regular-sized water-melon is now grafted, and the switch has happened quickly.

“This has been pretty big, within the last three years,” Zanotto says. “We went 100% grafted for the past two years.”

Despite the higher cost in using grafted watermelon, Zanotto says they’re worth it. Grafted plants can not only resist disease better, Zanotto says he’s seeing a more uniform fruit size, better harvest timing, and a longer-lasting shelf life.

Testing New Varieties and Inputs

Due to the number of acres it devotes to watermelon, Van Groningen & Sons has seed companies coveting its trial fields. The lucky varieties that make the cut will have about 15 acres to prove themselves on.

After harvest, the operation not only measures yield but also Brix, fruit texture, visual appeal, and any other feature that impacts marketability. The sales team is invited to help make those measurements.

It’s a simple assessment, Zanotto says. “It’s just sales, really,” he says. “Could we sell this?”

Once the team decides to move forward with a crop, they work it into the crop list carefully.

The same concept applies to new inputs. Start with a trial and compare the results with existing products. If the team likes what they see, they’ll incorporate it slowly into acreage.

That minimizes the risk and allows for adjustments.

“Maybe if it’s a new fungicide for powdery mildew, we’ll try it on a 10-acre field. If we like it, it’s not like we’re putting all our acres into it. We’ll just use it on like 250 acres worth this year and see. And then next year, we’ll include it on 500 acres,” Zanotto says.

All this said, the operation already has varieties and controls it’s happy with. The mix is working well for them.

“So we don’t really like to change it up a whole lot unless our program isn’t working,” he says.

That means Van Groningen isn’t running a lot of trials in any given year. “I think most of our trial work is done in plant varieties,” Zanotto says.

Know Your Field

“We try to be as sustainable as possible,” Zanotto says. “We’re not using harsh chemicals. We’re always rotating our active ingredients and group numbers.”

Another way to cut down unnecessary inputs is understanding what you’re dealing with. Part of Van Groningen & Sons’ routine is to take soil samples to test for nutrients at the beginning of the season. The team also tests for soilborne diseases.

“We can have a ballpark of what we’re going to deal with that season,” Zanotto says.

When it comes to powdery mildew or downy mildew, however, Zanotto is more aggressive.

“I would say for fungicide, we’re more on the preventative.”

American Vegetable Grower’s GROW STRONGER initiative brings you positive stories from progressive growers filled with innovative solutions to help you grow a stronger future.

Sometimes a disease outbreak still occurs, despite a quality IPM program and a solid input schedule.

At Van Groningen, the crew follows a tried-and-true protocol.

Step one is to check the watering schedule and the mechanics of the irrigation system. Has a leak occurred? Did you accidentally overwater?

“Watermelon plants are very sensitive, so irrigation is super important. You don’t want to under water them. You don’t want to overwater them,” Zanotto says.

The next step is to pull up the roots of affected plants, looking for symptoms of different diseases.

“From there, we can make a management decision on what product we’re going to use,” he says.

At a Glance: Van Groningen & Sons Inc.

Owners: Robert Van Groningen, Dan Van Groningen, Bryan Van Groningen, Ryan Van Groningen, Jason Van Groningen, Paul Hiemstra

Founded: 1922

Crops: Almonds, alfalfa, silage corn, Indian corn, watermelon, pumpkin, gourd, and wheat

Size: About 5,000 acres

Customers: Grocery stores, fruit stands, and Blue Diamond for the almonds

![2023 Vegetable Seed Trials: New Pumpkins for the Picking [Videos]](https://www.growingproduce.com/wp-content/uploads/2023/12/Invincible_gallery-300x169.jpg)