Growers Offer Firsthand Perspective on Current State of the Vegetable Industry

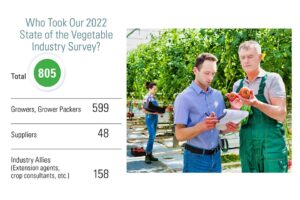

Welcome to our analysis of American Vegetable Grower’s 2022 State of the Vegetable Industry survey! We saw a lot of changes this past year, much of them driven by the pandemic, supply chain issues, and rising costs.

To help flesh out what the statistics show, we reached out to three of the 805 survey respondents. Scroll the gallery above for some interesting takeaways from this year’s State of the Vegetable Industry survey.

These growers tell us what’s going on behind the answers they gave us.

Bob Jones, Jr. CEO, Chef’s Garden

Location: Ohio

Size: Protected ag: More than 10 acres. Overall: 100 to 500 acres

Customers: Direct-to-consumer and national restaurants

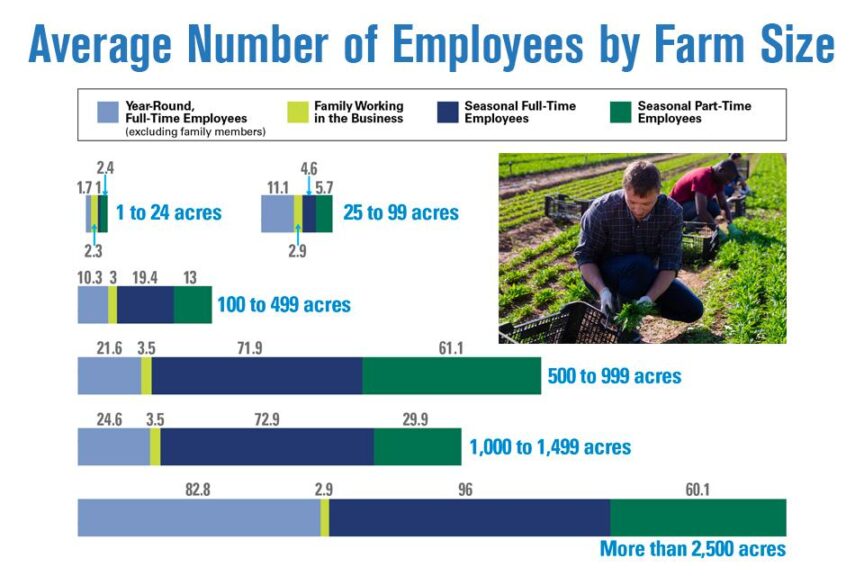

Employees: 150 full time year-round, plus 25 seasonal, and eight family members.

Bob Jones

American Vegetable Grower (AVG): You grow a wide array of crops. It looks like you’re not cutting back on any of them and are increasing production on more than half. What do you think is driving the increased demand?

Jones: Our production decisions are made by a team of folks here on the farm that receives input from the sales team, marketing team, our production schedulers, and the growers themselves. We look at the previous year’s demand (voice of the customer), new business, and projections of new business as well as requests for new items.

We are in a growth mode, post pandemic. Prior to the pandemic, we were a restaurant-centric operation. We have since added a home delivery model and a retail outlet on the farm. And those additions have caused us to modify and increase many items and to decrease a few as well.

We, like many farming operations, had to diversify our operations as a result of the ever-changing business climate we find ourselves in the midst of currently. We are vegetable growers at heart. And we want to help as many people along our path as possible. Customers, our team, our vendors, and our community.

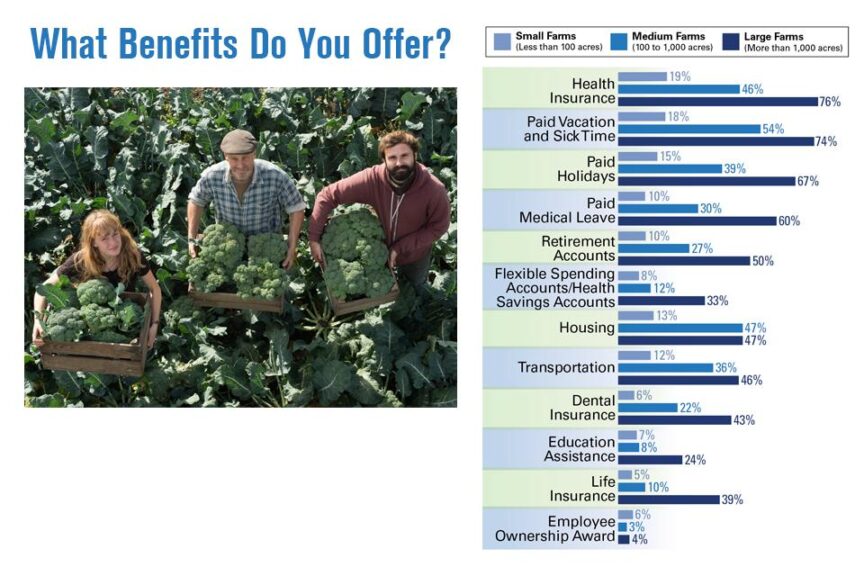

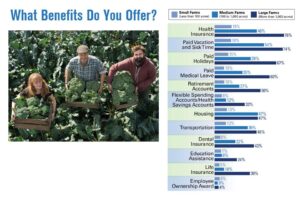

AVG: You offer more employee benefits than most growers. What’s your strategy behind doing so?

Jones: We are blessed to have six members of generation three currently working in our operation. That generation asked us to review and update our benefits program. And it only made sense in this labor market to do everything we could to recruit and retain our current team by being as competitive as possible in this arena.

As we all know, agriculture is never going to out-compete on wages and benefits. However, when we asked our team what was important to them, they told us. And we tried to respond accordingly.

Being a year-around grower/packer/shipper helped in that regard, as well. We are blessed to have an amazing team that we work alongside every day. We have about 150 in our farm family. We are even related to some of them!

We found that as our population on the farm ages, different things are increasingly important to them now. And we all must ask, listen, and respond to our teams.

Most business books that address employee engagement refer to the top 10 reasons why folks work where they do. We found it quite interesting that money ranks eight, nine, or 10 on most lists.

The key, then, is in discovering those top seven reasons and addressing them the best we can.

Typically, we have found that our team — and most all of us, actually — have an innate desire to be noticed, heard, and appreciated. These are not typically things you think about when engaging teams on the farm. However, today is a new day, and we must evolve in our practices or be left in the dust!

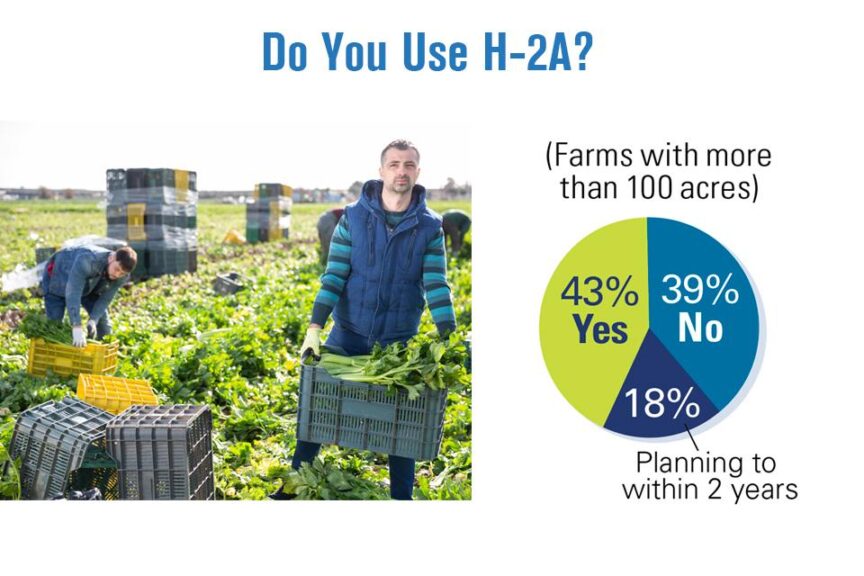

AVG: What percentage of your team do you hire through H-2A?

Jones: Our seasonal staff is H-2A, and we also have about 15 full-time Green Card holders who have graduated from that crew and are now here year-around with their families.

That has been very rewarding, to bring families together through the legal immigration process. It is a long, arduous, and expensive process. But it has been very gratifying to bring together families that typically have spent seven to eight months apart from each other every year.

20% of all vegetable growers use H-2A

48% of growers with 1,000 to 2,500 acres use H-2A

Many of these children had never spent a summer with their dad in their lives! The children have done incredibly well in school, as they seem to really appreciate the opportunities our educational system provides.

I think many of us as Americans have taken our lifestyles for granted. We really are a blessed people in this country.

Bruce Frasier President, Dixondale Farms

Location: Texas

Size: 1,000 to 2,500 acres

Customers: Supermarket, direct-to-consumer, and food service

Crops: Onions and cantaloupe

Bruce Frasier

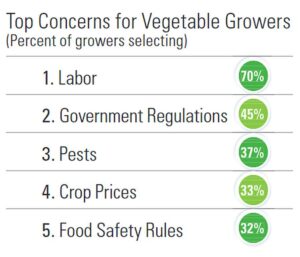

AVG: You selected several challenges you’re facing — labor, food safety rules, regulations, crop prices, succession planning, and increased demands from buyers/retailers. How are you addressing them?

Frasier: For the first time in history, we have had to supplement our local labor force with H-2A workers. Since everyone gets paid that higher wage, it is definitely our biggest concern and expense.

We are the largest cantaloupe grower in Texas, but that is the only crop we grow besides onion plants. That means all our food safety expense is attributed to just one crop.

Our customers are generally under-standing of a price increase. But they have to maintain a price that will keep our product moving. We have to remember that the consumer doesn’t have to buy our products.

Regulations are just something we have to deal with. One challenge is finding [out] about new regulations that are required. Since we deal with all the states, we sometimes don’t find out we need to do anything until the product has been delivered.

Succession planning is always on my mind. But now my customers are starting to get concerned about it.

They wonder what we are going to do once I can’t do this any longer. The employees are concerned about it, as well. And they are so capable of getting everything done, they are confident things can still keep going once I am gone.

Interested buyers are more concerned about replacing me than anything else. Finding someone who has the dedication and [is] willing to make life sacrifices is a difficult task.

AVG: You’re using automation in several areas — harvesting, planters, and steering. Is there anything new you’re keeping your eye on? What captured your interest?

Frasier: We have email campaigns for our onion plants. Using automation to educate customers is complicated at first. But outsourcing this technical expertise is the way to go for small producers.

We developed our own onion plant harvester in Belgium, and the price was relatively cheap. We just let it sit at the barn and the employees know we have that as a backup if they don’t get the job done.

What they don’t know is that it really isn’t that much of a savings in labor costs. We still have to have several people putting the final touches on the packing before they can be shipped. We just have one machine and would need 20 people to get everything harvested.

48% of vegetable growers use precision agriculture tools

Only 11% of those growers use auto harvesters

The automation in farm equipment has made it easier to put anyone on a tractor for a particular task. We had a tractor driver by the name of Israel back in the 70s and 80s. He was so proud of his expertise on making the rows that he would probably cry if I ever had anyone else even consider doing that. We joked he could go around the world and come back to the same spot.

Well, Israel died, and we didn’t have anyone that had any training on making the rows. And it was difficult for a couple of years. With this technology, I could replace Israel with almost anyone who could drive a tractor.

Planters have become a big savings by placing exactly one seed at the right spacing and the right depth. With seed costs going up every year by a minimum of 3%, I expect more this year.

Christopher Coelho Crop Manager, Woolf Farming

Location: California

Size: More than 2,500 acres

Crops: Processing tomatoes and fresh market garlic

Christopher Coelho

AVG: You mention that while your crop prices are up, they’re not up enough, considering production costs have more than doubled. What do you think needs to happen to change things?

Coelho: The only real and immediate adjustment that a producer of an agricultural commodity can do is to drive efficiencies and innovation within the operation to dampen the effects of input inflation.

The single most important thing that needs to happen at a macro scale is legislation to level the playing field. Make it so added costs associated with the past 10 years of tightened regulation on domestic producers is reflected as tariffs on imports from countries that enjoy the benefit of our market without bearing the same costs that are placed on domestic producers.

Until that happens, quality and quantity of food goods available to consumers will be diminished. California has both the resources and ability to produce more. But it cannot happen without better management at a governmental level.

AVG: Last year’s drought impacted your production in a significant way, like just about every other California grower. How is your operation meeting these challenges? What actions could others take?

Coelho: Successful growers will do what they have always done in hard times. And that is innovate and adapt.

Operations like ours will shift their crop mix to less water-intensive crops, as well as invest in more solar projects. Both will reduce supply of currently available commodities, driving up prices further.

Another issue will be covering overhead costs, given that most operations will have to reduce the amount of land they are currently farming. This will be a major challenge for operations as their footprint shrinks, and many small- to medium-size farms will be absorbed by larger organizations that are able to withstand the changing environment.

Being nimble and a top producer will not be enough if the organization is not of a large enough scale. Some growers will opt to farm water rather than crops.

The positive result will be opportunities for companies that are sized correctly to acquire adjacent properties that allow them to better move their available water.

Lastly, as a company, we are looking into cover crops on fallow fields. We don’t have the water to farm all the acres. And we have been successful this season harvesting hay off a diverse, fall-planted cover crop without any irrigation other than rainfall. Several fields grew more than 3-feet tall and produced several tons of dry biomass, all while supporting native pollinators.