Why One Small Vegetable Farm Adopted Mechanization

When Gail and Paul Fenton started their vegetable operation the year they married (1985), finding local workers was easy. Farm work was a popular summer job for high school and college students. Then, like farms across the U.S., they have watched their labor pool shrink.

The Fentons are the types of growers who always look ahead and evaluate how to improve their methods to keep Batavia, NY-based Fenton’s Produce, LLC, profitable.

“I have witnessed their transformation from humble beginnings to a full-fledged successful vegetable farming enterprise,” says Robert Hadad, Extension Vegetable Specialist with Cornell Cooperative Extension. “I respect these folks a lot.”

The Fentons regularly conduct trials on their 60-acre operation, both independently and with Cornell University. When labor began tightening, they took the same approach to solving the issue.

Today, Fenton’s Produce consistently seeks out new equipment — and innovative ways to use that equipment. Their secret source? YouTube.

Bringing the World to Fenton’s Produce

The Fentons have equipment from sources as far afield as France and the Netherlands. But they aren’t spending a lot on travel.

“We don’t leave the farm,” Paul says. “We start on YouTube.”

He says he seeks out grower videos on how they’re handling issues on their own farms. Those videos are an invaluable source of advice — and equipment leads.

How they find the best videos is straightforward.

“It’s simple. What are you looking for? Punch it in, and it’ll bring up stuff,” Paul says with a laugh. “Then it’ll bring you into a farm and, oh wait, this farm has a ton of posts on here! Let’s go in and see what they’re doing. How do they do this or how do they manage the weeds?”

If they see equipment that may work for them, they hunt down the company and either find a U.S. distributor or contact it directly. The internet shrinks the world, making almost anything accessible.

They prefer seeing how equipment works on working farms over company-based, online demos.

“You’ll only see perfect conditions on those videos — no mud, no rocks,” Paul says. “I’d rather see how it really works for someone with a farm like mine.”

Whereas peer videos show a great deal more than just the equipment.

“You pick up all kinds of hints or techniques that they’re using to make this machine work, or even varieties that work great in their houses,” Paul says.

Making Labor Easier

One company the Fentons discovered from a YouTube video is ASA Lift, based in Denmark.

“We have a couple pieces of their equipment on the farm,” Paul says.

One is a lifter for root crops.

“It’s just a vibrating knife that’s going under the crop to lift it up, loosen it, and then set it back down. We will then come along and gather up the crops by hand,” Paul says.

It prevents manually pushing a tool into the soil, possibly not loosening the garlic or other root crops enough and snapping them. It also lightens the physical drain of pulling hard.

“We added it only a year or so ago, so we’re still experimenting with it a little bit,” Gail says.

Another example is a leafy greens planter ideal for small farms from Paperpot Co.

“It is a transplanting system for small, leafy crops that are spaced very close together and that are very labor intensive to plant,” she says.

Customizing to Their Needs

Like any vegetable farmer, the Fentons tend to modify equipment. “Farmers are notorious for taking a brand-new piece of equipment and taking the welder torch to it,” Paul says.

And sometimes they simply expand an equipment’s tasks. Take the battery-operated clippers they bought for their blueberry bushes. While they still use the clippers primarily on blueberries, they also make harvesting Brussels sprouts and butternut squash easier.

Speaking of Brussels sprouts, the Fentons use a sprout machine to snap sprouts.

“By the time you get to the 75th or 100th stalk, your thumb is so sore from snapping them,” Gail says.

Competitive Advantage

The right piece of equipment is a game changer for a small farm. For Fenton’s Produce, a simple potato bagger gives them a competitive advantage.

Most potato baggers go for large quantities — 50 pounds and up. The Fentons use one that allows them to create small, customizable bags.

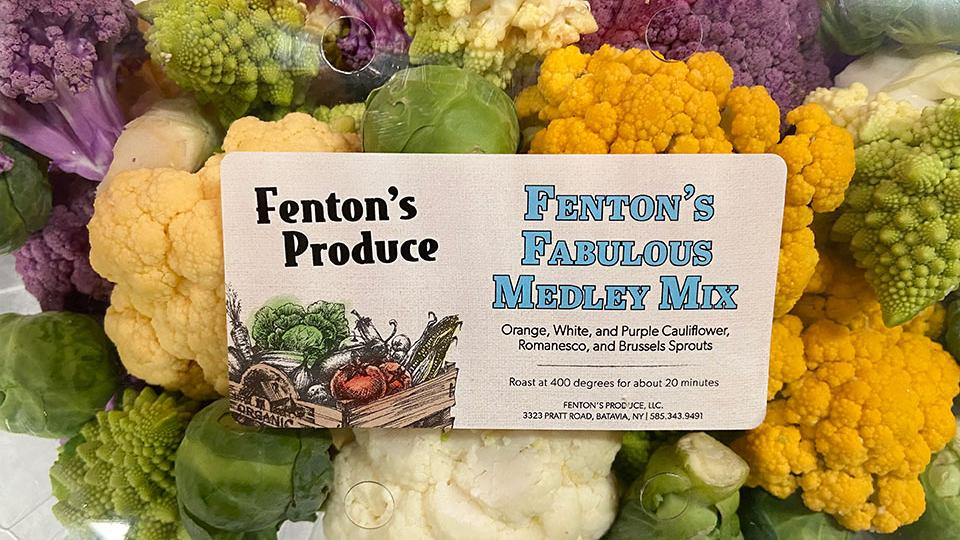

It’s so versatile they can cater to almost any customer demand. Need a 5-pound bag of mixed roasting vegetables? They can do it. It’s allowed Fenton’s Produce to offer custom blends, setting them apart from other farms.

“We have a green and yellow beans mix. Two weeks ago, we did a blend of different colors and types of potatoes,” Gail says.

The flexibility also gives them a way to sell product that may not sell otherwise. And anytime you’re able to offer a unique product, your odds of getting a premium price goes up.

The Fentons are proving that no farm is too small for sophisticated equipment. In fact, they’re showing that smaller farms need these tools to remain competitive.

At a Glance: Fenton’s Produce, LLC

Owners: Gail and Paul Fenton

Founded: 1985

Location: Batavia, NY

Size: 60 acres

Customers: Grocery stores, distributors, CSA, on-farm marketing

Crops: Wide array of vegetables and some fruit (blueberries, strawberries, and grapes)